Welding fumes contain pollutants such as heavy metal particles and harmful gases (such as ozone and nitrogen oxides), and prolonged inhalation can seriously harm workers' health. Traditional ventilation equipment fight to completely solve this problem, while modern welding fume purifiers, through the integration of high efficiency filtration systems and intelligent control technology, have become key equipment for environmental upgrades in industrial workshops.

Welding fume extractors use a multi-stage filtration system. First, primary filtration intercepts sparks and large dust particles, protecting subsequent filter elements. Then, a high efficiency PTFE coated filter cartridge achieves a filtration efficiency of ≥99.9% for 0.3μm particles, effectively capturing PM2.5 and heavy metal particles in welding fumes. The pleated filter cartridge structure increases the filtration area and extends service life; some models equip with pulse back-flushing cleaning system to automatically clean the filters and maintain stable airflow. The fume extractors equip flexible suction arms or overhead hoods to directly extract fumes before they spread.

The intelligent control system built into the welding fume purification equipment can monitor key parameters such as smoke concentration and filtration efficiency in real time, and automatically adjust the suction airflow and filtration mode according to actual conditions to achieve energy saving, consumption reduction, and intelligent management. The equipment also features fault warning and automatic alarm functions. If an abnormality is detected, such as filters blockage or motor failure, the system will issue an alarm immediately, notifying relevant staff for handling, ensuring stable operation and safe production.

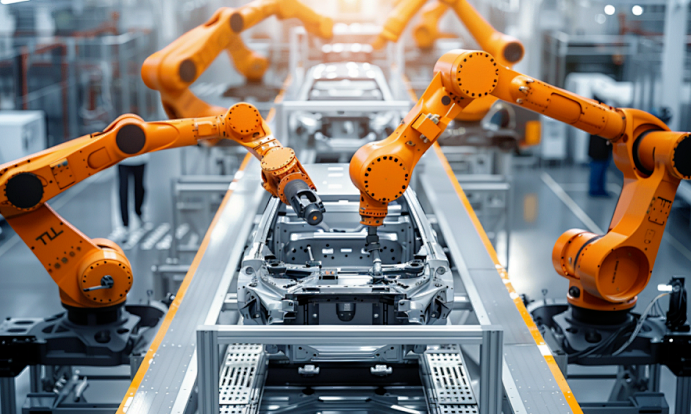

With industrial development, welding dust collectors are transforming from "single purification equipment" to "intelligent environmental protection terminals." In the future, technologies such as AI algorithms to optimize airflow distribution and linkage control with welding robots will further unlock the industry's potential, providing smarter solutions for "dust-free workshops."

The application of welding fume extractors not only protects the health of operators and reduces the risk of occupational diseases caused by long-term exposure to harmful fumes; it also improves the air quality in production workshops, enhancing work efficiency and product quality. At the same time, it helps enterprises achieve green production, improving corporate image and market competitiveness.