-

CaseMar 06, 2026Dust collection artifact I Environmentally Friendly Polishing Dust Collection Cabinet Read More

-

CaseMar 04, 2026Laser Welding Dust Removal Project at a Tianjin Automotive Parts Co., Ltd Read More

-

CaseMar 02, 2026Strengthening the Environmental Protection Line in the Workshop and Safeguarding the Health of Workers – Dust removal project for welding, polishing processes in Jiangsu livestock machinery production workshop Read More

-

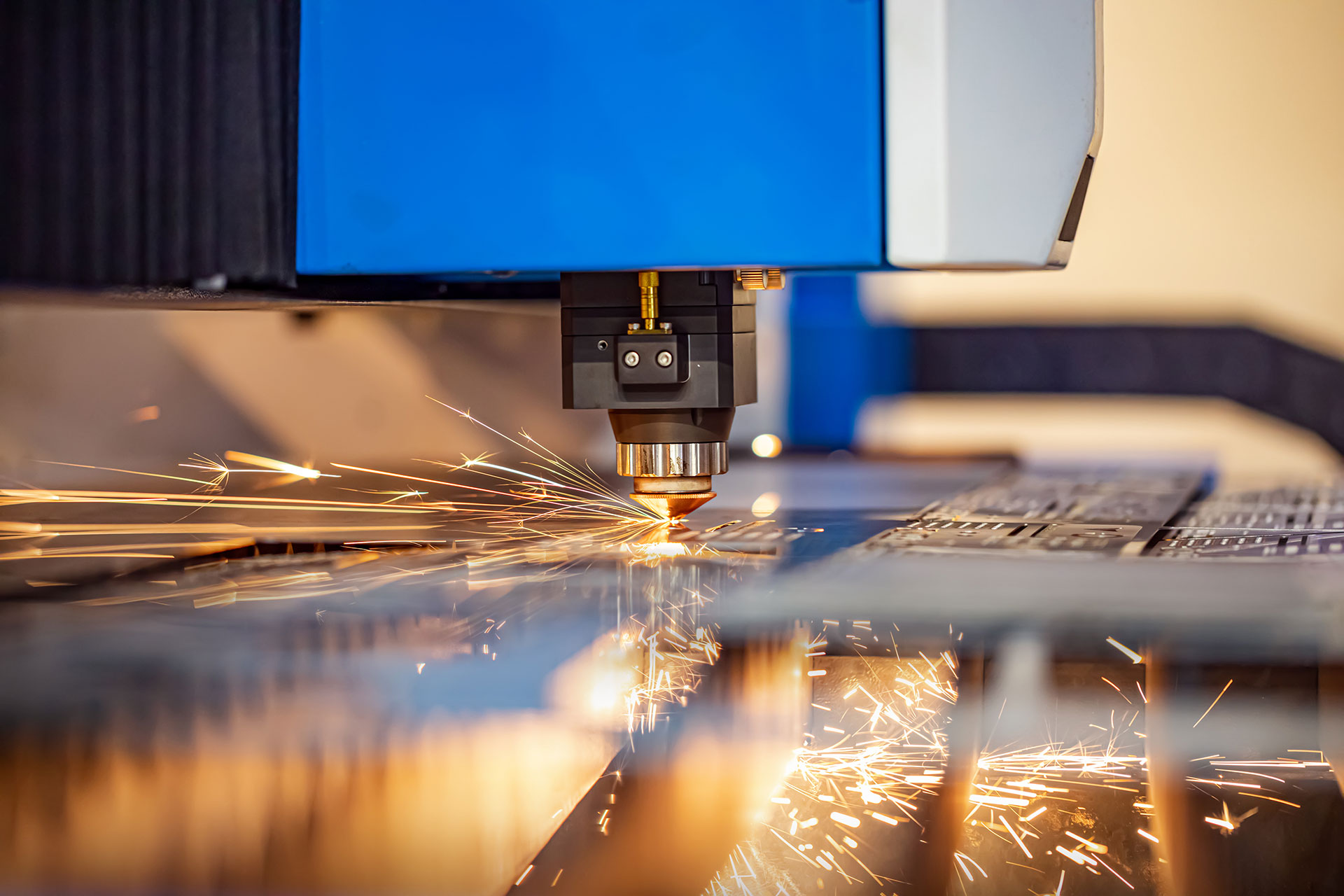

CaseFeb 27, 2026Dust Removal for Plasma Flame Cutting Machines: Targeted Solutions and Selection Considerations Read More

-

CaseFeb 25, 2026Laser CuttingDust Removal Project for a Special Vehicle Company in Chongqing Read More

-

CaseFeb 13, 2026Welding Workshop Overall Fume Dust Extraction Project For An Electric Vehicle Manufacturer in Jiangsu Read More