Welding fumes are the main pollutants generated during welding operations, containing metal oxides, harmful gases, and ultrafine particles. Long-term exposure poses significant risks to workers' health and the environment. Effective fume collection is a core aspect of controlling welding pollution, and its efficiency directly affects the subsequent purification effect. Therefore, this article mainly introduces the characteristics of welding fumes and several methods of welding fume collection, providing a reference for industrial applications.

Welding fumes originate from the combustion and evaporation of welding materials at high temperatures, and metallurgical reactions of the base metal. They have a complex composition, containing particulate matter, heavy metal vapors, and nitrogen oxides. Their particle size distribution is wide; small particles are easily suspended in the air and can penetrate deep into the lungs, causing respiratory diseases. Due to high-temperature characteristics, the fume generation location is not fixed, increasing the difficulty of collection. Long-term inhalation can lead to occupational health risks, such as nervous system damage, meanwhile also polluting the workshop environment and reducing production efficiency.

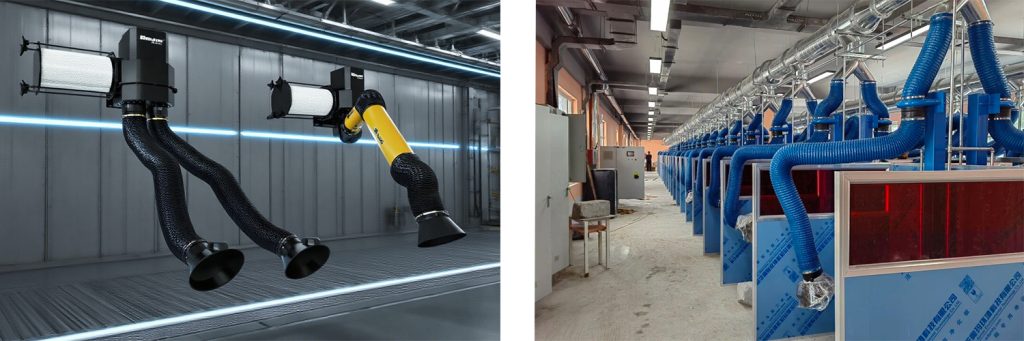

1. Suction Arm Type

This method is suitable for situations where welding points are concentrated and welding stations are fixed. The suction arm can rotate universally and remain suspended in any position. Therefore, the worker can easily adjust the suction hood position and enabling fume collection at the source.

2. Welding Room Type

This method is suitable for conditions such as automatic robot welding. Usually, a fume extraction port is installed at the top, connected to a dust collector via a pipe.

3. Retractable Room Type

This method is suitable for welding large workpieces, especially when the workpiece requires crane handling and factory space is limited. The retractable booth can be retracted when not in use, freeing up space for other purposes.

4. High-large Workshop Blow-Suction Fume Extraction System

This fume extraction system uses evenly distributed blow and suction vents through piping, with airflow balanced at the end vents through fluid dynamics analysis. So that ensure effective fume and dust collection at each suction vent, and prevent airflow loss along the way.

5. Overhead Suction Hood Type

Suitable for situations where welding points are fixed. An overhead suction hood is installed in the single-station welding area to achieve regional fume extraction and purification.

When choosing fume collection method, enterprise should make a comprehensive decision based on factors such as their welding conditions, the distribution of welding points, workpiece size, and workshop layout.