This project involves a new workshop for an electric vehicle manufacturer in Jiangsu Province.The welding area spans over 30,000 square meters. It is planned to accommodate 300 welding robots and 860 manual welding stations. All welded parts are components used for electric tricycles.After multiple rounds of communication and on-site surveys, the customer finally chose Moland’s blow- suction welding overall fume extraction system for the workshop.

Workshop Treatment Area: The workshop consists of 8 spans. This 8 spans are 180 meters long and 20 meters wide. So the workshop volume is 180,000m³.

According to the national standard, the total dust concentration in flue gas must be ≤4mg/m³.

We determined the air exchange rate based on the ventilation manual and indoor pollutant concentration. We set the air exchange rate at 8 times per hour. This gives a total design air volume of:180,000 × 8 = 1,440,000 m³/h. Meanwhile, we also accounted for air volume loss and duct resistance.

Therefore, to meet the required air volume, we recommend at least 70 units of MLWF2000‑C blow‑suction dust collectors. Each unit provides an air volume of 20,000 m³/h. In total, they deliver 1,400,000 m³/h.

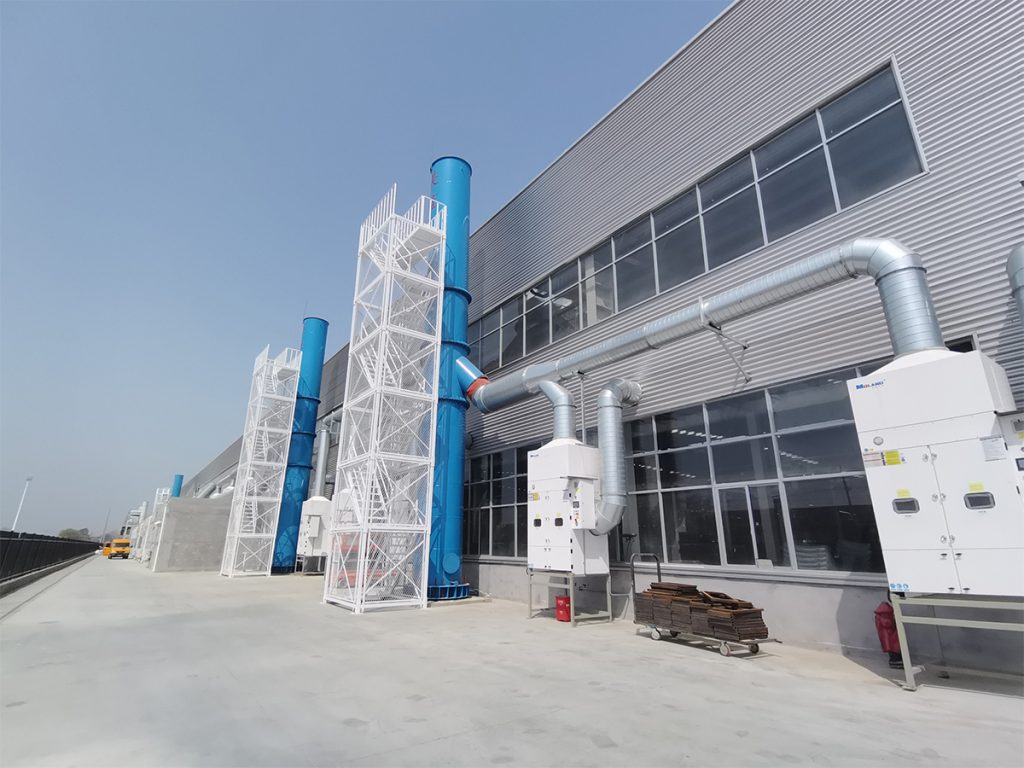

15 sets of air supply fans on one side of the workshop blow air towards the middle span. The dust removal unit in the middle span is purified by negative pressure. Then the clean air discharged is converted into air supply power to continue to be discharged to the adjacent span. This process continues, and the airflow in the entire workshop forms an air curtain facing one side. Finally, the air is purified by 18 dust removal devices in the last span and discharged outdoors in an organized manner through 3 chimneys. Each exhaust stack is 16,000 mm long and has an exhaust volume of 120,000 m³/h. The total exhaust volume is 360,000 m³/h.

The fume extractor uses advanced fine filtration technology. It adopts premium PTFE coated flame-retardant filter cartridges and maintains stable and high-volume airflow at all times. It captures 99.9% of 0.3μm dust particles efficiently. First, dust collectors capture welding fumes and exhaust gases. They use strong suction from the negative pressure fan. Then, pipes carry these fumes into the equipment inlet. A guide plate distributes fumes evenly into the settling chamber.

Coarse dust drops into the dust drawer by gravity and airflow. Diverted fine dust sticks to the surface of filter cartridges. The system monitors air resistance with a pressure sensor. When resistance rises, the controller opens valves one by one. This protects the system from losing airflow performance. It then starts automatic pulse backflushing and cleaning. Dust falls smoothly into the dust collection bin. Filtered clean air flows out from the cartridge center. It enters the clean air chamber and exits via the outlet. The discharged clean air fully meets national emission standards.