Recently, a large-scale iron tower manufacturing company in Hebei Province successfully completed its centralized welding fume extraction system project. The project, custom-designed by Moland, employs dual fume collection method combining blow-suction and cantilever systems. The two modes can switch at any time, precisely adapting to the multiple welding conditions encountered during iron tower production. Therefore, it completely solves the industry pain point of difficulty in capturing and thoroughly purifying welding fumes from large structural components.

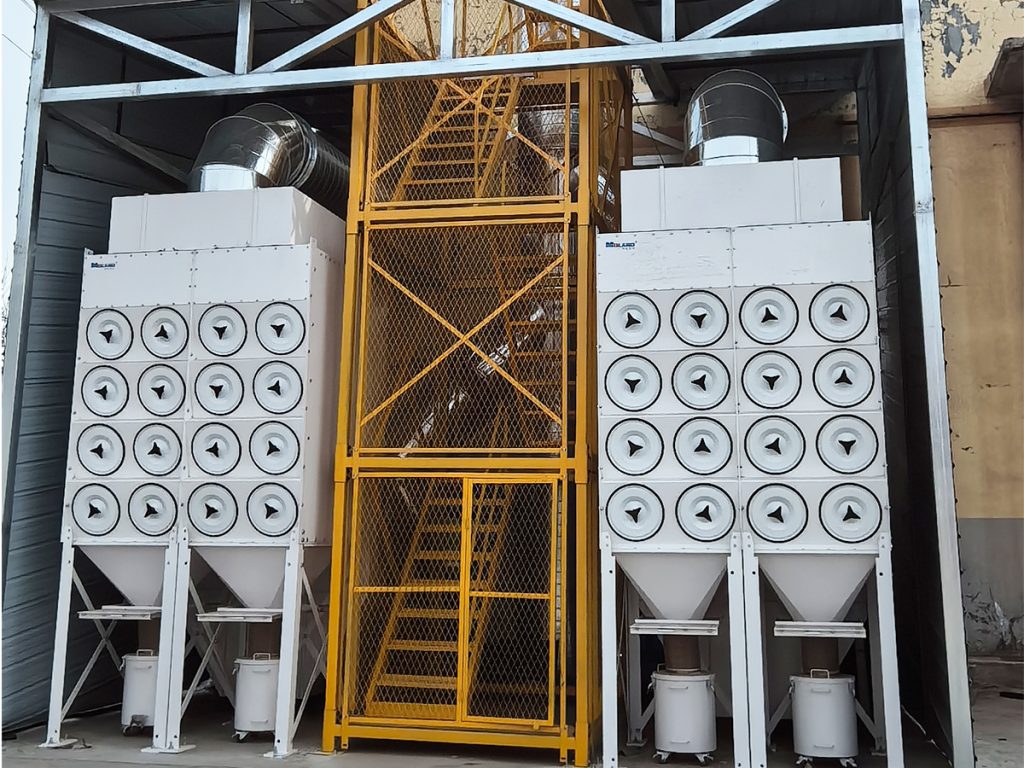

Based on the site conditions, Moland install a 10,000m^3/h frequency conversion dust collector and a 7.5 kW supply fan.

The dust collection project employs a dual dust collection method combining blow-suction and cantilever systems. The method not only satisfies the on-site dust purification needs, but also meets various environmental protection department testing requirements. Blowing and suction ducts are laid on both sides of the workshop, with several grille vents distributed along the ducts. Each vent has an individually controlled valve, allowing the number of vents to be opened based on the location of the dust generation. The cartridge dust collector automatically adjusts the airflow according to the number of vents open. This achieves energy saving, emission reduction, and high efficiency in environmental protection.

The combined blow-suction and cantilever collection method not only achieves comprehensive purification of welding fumes and dust, ensuring that the air quality in the workshop meets standards, but also complies with the multi-form testing requirements of environmental protection departments, helping enterprises successfully pass environmental compliance acceptance. As a high-tech enterprise specializing in industrial fume purification, Moland always adheres to the concept of customized solutions, combining its excellent professional technology and rich industry experience to provide customers with full-process services. It anticipates the replacement and maintenance needs of equipment components and parts in advance, promptly carries out maintenance work, effectively avoids production safety hazards, and safeguards the normal and safe production of enterprises, winning high recognition from customers.