A power equipment manufacturer in Shanghai produces dust and fumes during welding, grinding and cutting. To upgrade the production environment, protect employee health and boost work efficiency, the company has thus adopted Moland’s dust collection system for dust and fume treatment, ensuring emissions fully comply with regulatory standards. Today we'll share this dust removal case.

Given the on-site conditions, we select the MLWF3000C dust collector for welding fume treatment. It boasts 22KW power, 30,000 m³/h air volume and 345㎡ filtration area. The system is fully automatic with one-button start. It supports multiple control modes, automatic dust removal and offline backflushing. The air duct uses a dual-suction method, and the dust removal pipe is fitted with multiple suction ports: welding fumes get drawn into the duct and flow into the main dust removal unit, the collector then purifies the fumes through filter cartridges, and finally expels the purified air in full compliance with standards.

The customer's grinding area has a 12m x 12m grinding room and a MLWF1600DM model grinding dust collection cabinet. The grinding cabinet is with an air volume of 15000 m³/h and a filtration area of 80m².

We install the grinding cabinets on both sides of the grinding workshop, which adopt a purification mode with bottom and top exhaust. When grinding operations generate dust, it enters the cabinets through the air inlets and first passes through the baffle plates; these plates disperse the dust-laden gas evenly around the filter elements. As the gas moves through the system, dust adheres to the outer surfaces of the filter elements, and the clean, filtered air is then vented outdoors through the air outlets at the top of the cabinets.

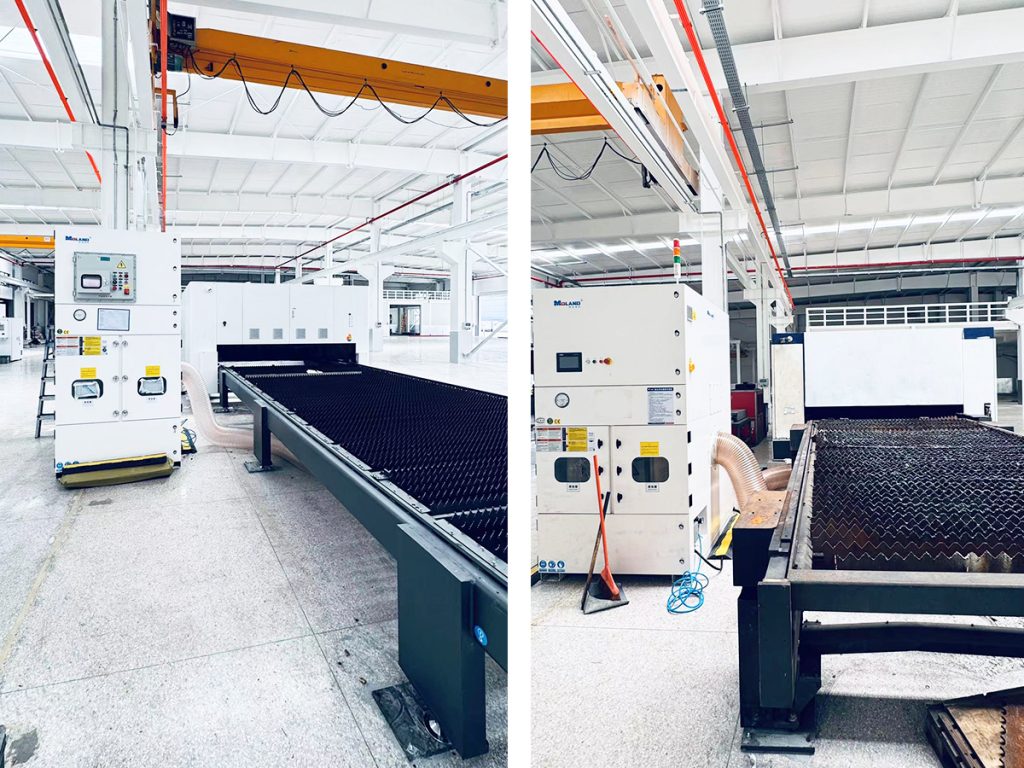

The customer’s cutting area houses two large enclosed 6025 laser cutting machines with exchange tables. Since these two machines process different materials, we’ve outfitted them with tailored dust collection systems based on the unique properties of the smoke and dust each generates: one is fitted with a 10,000 m³/h explosion-proof dust collector, and the other with a 10,000 m³/h intelligent dust collector.

We place two dust collectors at proper positions on the laser cutting machine. First, we connect the dust remover’s air intake to the machine’s reserved air duct with a PU hose. This way, cutting dust is collected right at the source, and normal production remains unaffected. The dust remover then purifies the collected dust and discharges the air up to standard.