The spacious, high-ceilinged workshop is plagued by rampant dust, severely impacting the production environment and employee health. Don't worry! Moland blow suction type dust collector is your savior!

Blow suction type dust collector equipped with a high powered fan, and powerful suction. It can quickly suck welding smoke and dust. Even fume and dust hidden corners are also mostly cleaned. The dust colector equipped PTFE flame retardant coated filters, and the filtration accuracy of 0.3μm, effectively intercepting fine dust. Meanwhile, the purified air can meet emission standards.

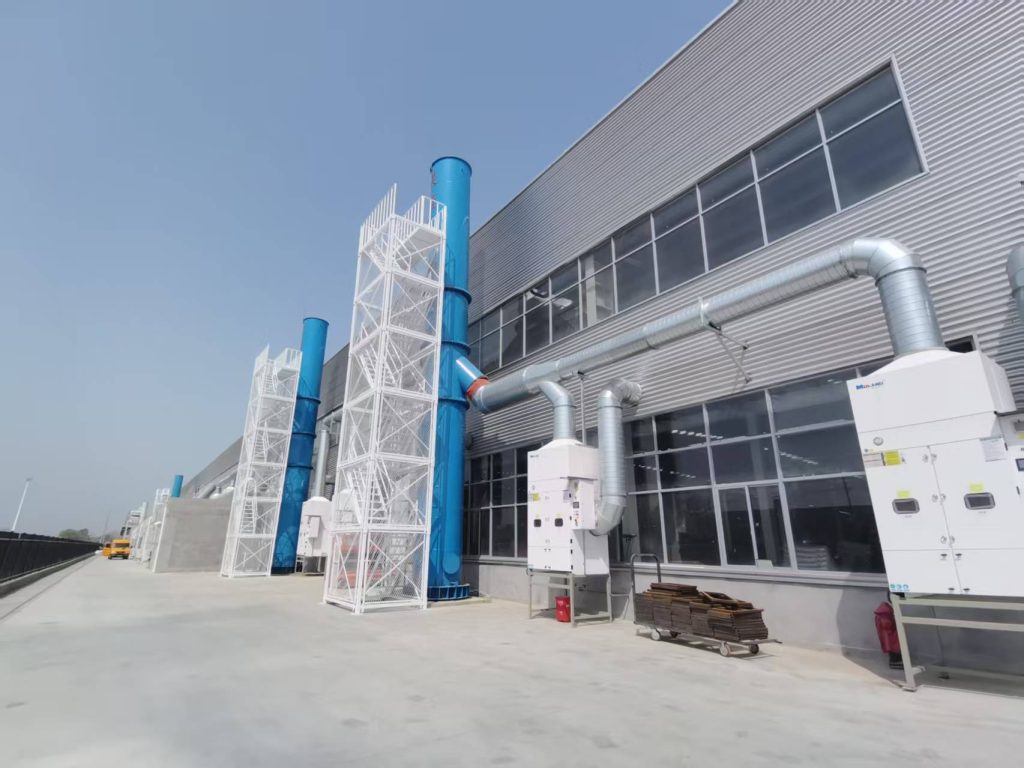

From smoke and dust environment to a clean and dust-free environment, the blow suction dust removal system has witnessed miracles in the welding workshop.

The blow suction type dust collector mainly consists of air outlets, air inlets, fans, piping systems, and filtration systems. The principle is as follows:

Install dust collection hoods at fume and dust generating points within the workshop. Design of the hoods should according to the characteristics of dust generation. And then using aerodynamic principles, fume and dust suction into the piping system along with the airflow.

The pipe of connecting hoods route according to the workshop layout. Using fan to generate negative pressure create a stable airflow within the pipes, meanwhile rapidly conveying the dusty air. This establishes an invisible “high-speed channel” throughout the workshop, swiftly transporting fume dust away from the source.

Dusty air enters the dust collectors, where it is evenly dispersed across each filter by the deflector plate. Dust particles are trapped and adsorbed on the filter surfaces, while clean air passes through the cartridges and exits. The filters purification efficiency to 99.9%, and can effectively removing fine dust particles.

As the filter usage time increases, the dust on the surface of the filter gradually thickens. At this moment, the pulse cleaning system starts working, using compressed air to instantly backflush and shake the accumulated dust into the dust collection drawer. The collected dust need treat according to its properties, such as through recycling or safe landfill, achieving harmless dust disposal.