The pharmaceutical industry has strict requirements. Dust not only harms the workshop environment but also affects product quality. A shop dust collector is essential for effective dust management, ensuring a clean and compliant production space.

(1)Dust from Vibrating Screens

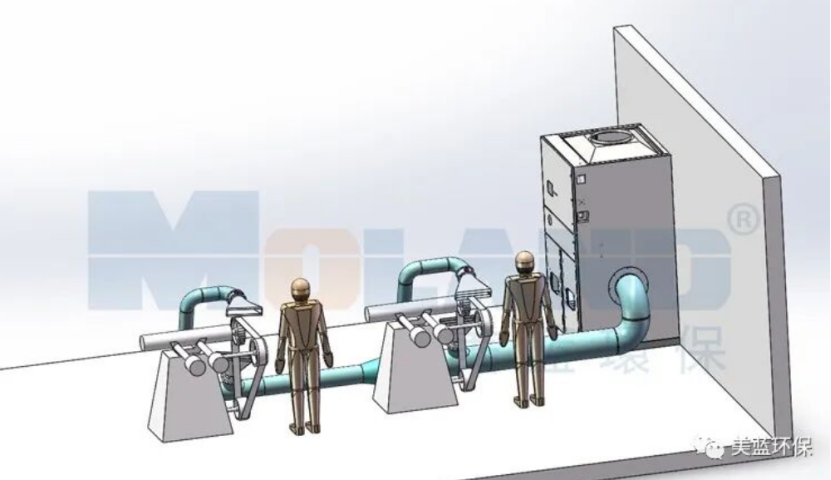

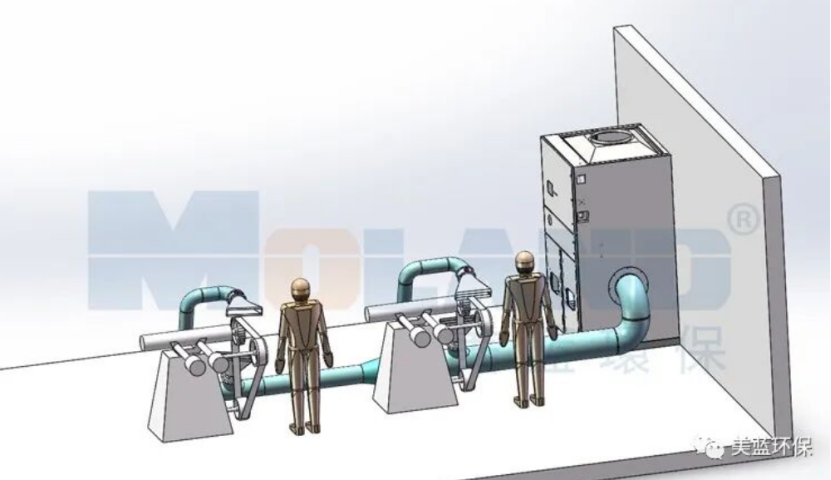

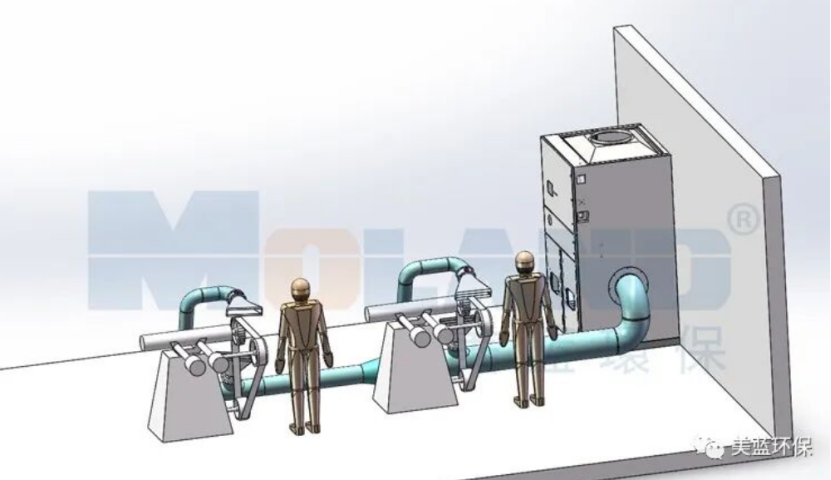

Vibrating screens make material particles move for grading. But they easily generate dust at end covers and discharge ports. To solve this, design side suction hoods at the operating height. Use food - grade flexible hoses to draw dust to an industrial dust collector for purification.

(2)Dust in Packaging Processes

After screening, packaging steps like weighing and sealing also release dust. The same side suction hoods and food - grade hoses can transfer dust to the shop dust collector, preventing pollution.

(1) Material Requirements

In pharmaceutical factories, suction hoods, pipes, and dust collectors usually need 304 stainless steel. This material meets hygiene standards and is durable.

(2) Powder Recovery

For recoverable powder, equip 304 stainless steel dust collectors and food - grade hoses. This enables powder recycling, turning waste into value for pharmaceutical enterprises.

A shop dust collector is vital in pharmaceutical production. It controls dust in various processes, ensures a clean environment, and supports powder recycling. To ensure cleanliness and compliance, you can choose Moland to provide you with a more professional solution