Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

①. Brief introduction of Laser Cutting Fume Extractor MLWF800

With the development of the industry, the working conditions of the on-site work stations are also diversified. According to the needs of the market and customers and different working conditions on the site, a special design is designed to be practical, beautiful in appearance, and closely coordinated (small footprint). . The equipment is required to be suitable for the recovery of dry, oil-free, non-corrosive gas mixtures, rare metals, precious materials and other dust generated in the purification production process. It is an ideal flue gas purification equipment in industrial processing.

The high-efficiency filtered air (clean air) can be directly discharged into the work area, and the dust will be cleared into the ash hopper during the automatic dust removal process. Thereby purifying the air quality of the plant, improving the working environment of the workers, and increasing the enthusiasm of the workers. After analysis and optimization and independent innovation of our company-Laser Cutting Fume Purifier MLWF800, this product has the fine fume generated by cutting, welding, grinding, industrial dust, etc. (standard filter element) can reach 99.7% of the filtering effect, which can be filtered out 0.3μm soot. The filtered air fully meets the national indoor emission standards.

The product is required to have the following advantages:

1. The product not only meets the relevant national norms and standards, but also satisfies the use requirements of actual working conditions. Product design requirements:

· Integrated design, compact structure, saving space;

· Vertical filter cartridge installation performance is stable, easy to replace, large filter area;

· Automatic dust removal button to automatically remove dust on the surface of the filter element;

· Power status monitoring, phase failure, overvoltage and undervoltage alarm, to prevent damage to motors and electrical components

· Air source status monitoring Alarm when air source pressure is too low to prevent incomplete dust removal

· Filter cartridge status monitoring Real-time monitoring of filter cartridge usage

2. The product should solve the feasibility and convenience of on-site use. Installation and operation are convenient, and structural innovations and breakthroughs must be achieved in maintenance, replacement of filter elements (quick assembly/removal of filter elements) and dust removal.

② Technical parameters of laser cutting fume extractor MLWF800

Model number: MLWF800

Work rate: 7.5kw

Air volume: 7000-10500m³/h

Precision: 0.3μm

Efficiency: 99.7%

Filter element: imported coated polyester fiber

Area: 90㎡

Ash cleaning: automatic pulse cleaning

Dimensions: 1240*1470*2550mm

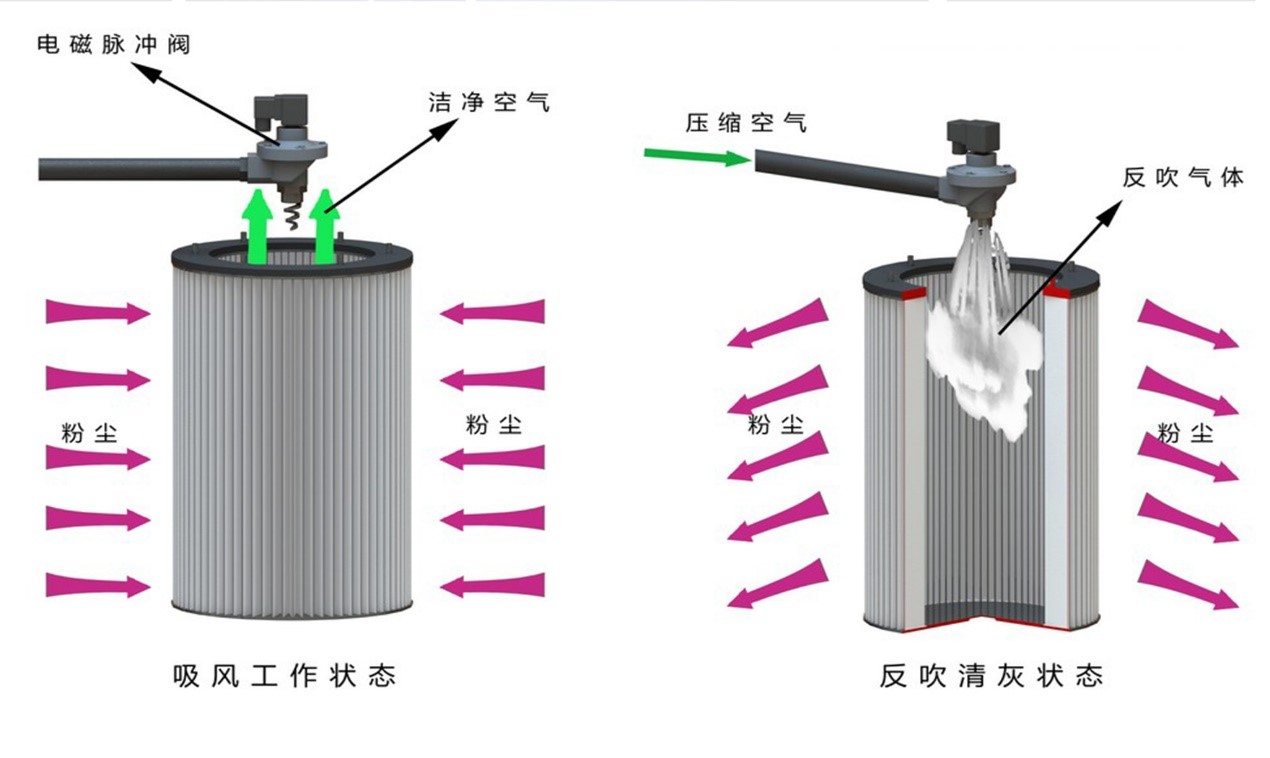

③ Features of pulse back-blowing dust cleaning:

When the pulse controller sends out the ash cleaning signal, the pulse solenoid valve opens quickly, and the compressed air in the storage cylinder quickly releases pressure. The air enters the filter cartridge at a high flow rate, causing the filter cartridge to expand rapidly, causing an impact and vibration, making it attached to the filter cartridge The dust on the outer surface is shaken off, and the fine dust adsorbed on the surface of the filter material is shaken off into the dust hopper under the action of the airflow.

When the signal disappears, the solenoid valve diaphragm re-closes the air injection port, and the injection stops automatically. Each time the blowing and cleaning is completed in about 0.1~0.3s, it is the high-pressure air sprayed at this moment that has a good cleaning effect. The pulse blowing air pressure is 0.4~0.6MPa, and the air supply must be kept constant during operation.

④. Features of filter material of MLWF800 series Smoke Purifier

The high-efficiency filter barrel is used as the filter element. The filter material selected for this filter barrel is different from the general traditional filter material, and its surface is attached with a layer of PTFE film. Traditional filter materials (such as cotton cloth, cotton satin, paper and other traditional cellulose, etc.) have a micro fiber gap of 5~60um. When the smoke passes through, a part of the dust particles in the smoke will enter the filter material and block the filter element; When the situation gradually deteriorates and effective dust removal is not possible, the air resistance of the filter element will increase, and the air flow rate that can pass will also decrease. If there is no automatic dust removal, the filtering effect will decline rapidly, and the extremely small sieve holes on the surface of the filter material of this series of purifiers can block most of the sub-micron dust particles; the sub-micron dust particles gather on the surface of the filter material and form a permeable barrier. Dust cake, most of the dust particles are blocked on the outer surface of the filter material and cannot enter the inside of the filter material, and can be removed in time and effectively under the blowing of compressed air. The filter material has a relatively high filtration efficiency, which is at least 3 to 5 times higher than the traditional filter material, and the service life is more than 2 times longer than the traditional filter material.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.