Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Working condition type: laser cutting machine dust removal

Project introduction:

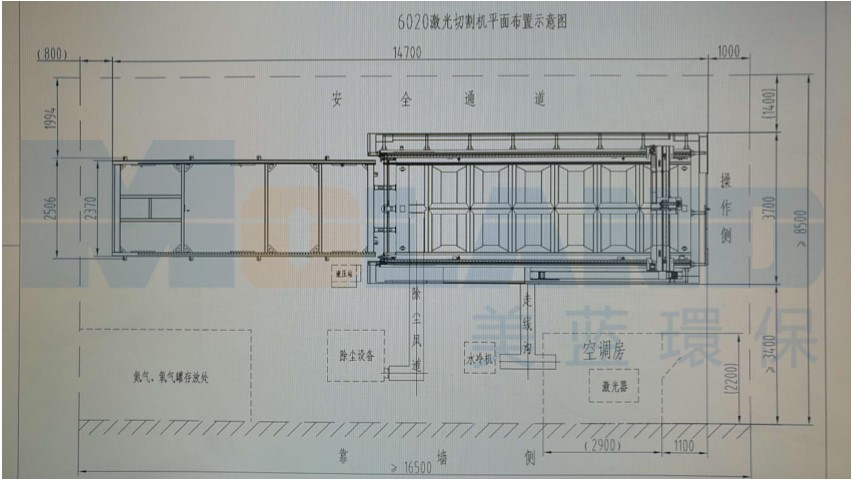

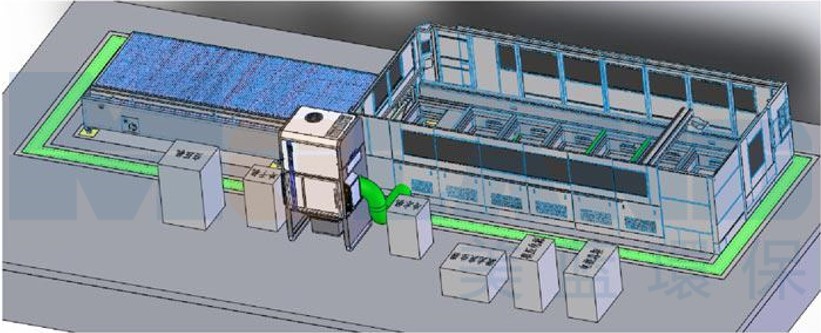

What needs to be treated this time is laser cutting dust removal. The main areas that need to be treated are:

Laser vaporization cutting: Under the heating of a high-power density laser beam, about 40% of the material vaporizes into steam and disappears, and 60% of the material is blown away by the auxiliary gas from the bottom of the slit as a spray, and combines with the fine particles in the air. Form dust.

Laser vaporization cutting: Under the heating of a high-power density laser beam, about 40% of the material vaporizes into steam and disappears, and 60% of the material is blown away by the auxiliary gas from the bottom of the slit as a spray, and combines with the fine particles in the air. Form dust.

Laser melting and cutting: When the power density of the incident laser beam exceeds a certain value, the irradiated material begins to evaporate, forming holes, and the material around the speed of light is melted. Then, the auxiliary airflow coaxial with the speed of light takes away the surrounding molten material, forming smoke and dust.

Laser oxidation cutting: The surface of the material is quickly heated to the ignition temperature under the irradiation of the laser beam, followed by a fierce combustion reaction with oxygen, releasing a lot of heat, forming a small hole full of steam in the material, and the surrounding of the small hole Surrounded by molten metal walls, these steam and molten substances are taken away by the auxiliary airflow and float in the workshop to form dust and smoke.

The hazard of smoke and dust is easy to be ignored by the operator. The high temperature generated by the laser acts on the processing material, and a large amount of steam and smoke are generated. These smoke contain a large amount of chemical components, which cause great harm to the human body. In addition, some gases produced by laser cutting (Such as carbon dioxide), it is more likely to harm the human respiratory system.

In view of the characteristics of laser cutting smoke and the requirements of treatment engineering, our company adopts a filter cartridge type purification treatment plan

Characteristics of MLWF series pulse filter cartridge Dust Collector

1. High-energy dust removal: it can remove dust particles efficiently, and the purification efficiency can reach more than 99%, which meets the national emission standards for air pollutants.

2. Strong adaptability: It can adapt to high concentration, air volume, and different working conditions. It can work continuously 24 hours a day, and the operation is stable and reliable.

3. The installation area is small, and the weight is light: suitable for special conditions such as compact layout and small space.

4. The filter cartridge adopts skeleton installation, with good sealing performance, firmness and reliability, long service life of the filter cartridge, and convenient installation and maintenance.

5. The box body adopts airtight design with good sealing performance. The inspection door uses excellent sealing materials, and the air leakage rate is low; the inlet and outlet air ducts are arranged compactly and the airflow resistance is small.

6. The dust collector adopts high-efficiency film-coated filter cartridge as the filter element, which has high filtration efficiency and long service life

The above methods can help customers solve the problem of factory laser cutting dust pollution.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.