Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Grinding and Polishing Downdraft Tables have been sought after by metal manufacturing enterprises. Why is that? Today we're going to talk about it.

As we all know, grinding is a necessary process in various industries, and many fine metal parts are carefully polished by workers, but like the welding process, polishing also has great soot pollution. The dust particles produced by polishing and grinding are extremely small and can be gathered in the workshop in large numbers, which will bring great negative impact on the workshop machine and the workshop environment. If not properly handled, it will not only bring safety risks but also affect the passing rate of the workshop EIA. Therefore, the problem of metal polishing, cutting and grinding smoke pollution has become a major problem in front of various metal manufacturing factories.

In the past, when people control the dust pollution of the polishing cutting and polishing workshop, they often take more traditional ventilation/industrial humidification and other methods, but these two ways have certain disadvantages, such as: workshop ventilation, for the polishing cutting and polishing workshop, the dust removal effect is there but not much, even if it is full power, the workshop is still covered with dust; The way of industrial humidification, although it can use water mist to condense the dust in the air and sink under the action of gravity, it will bring circuit.

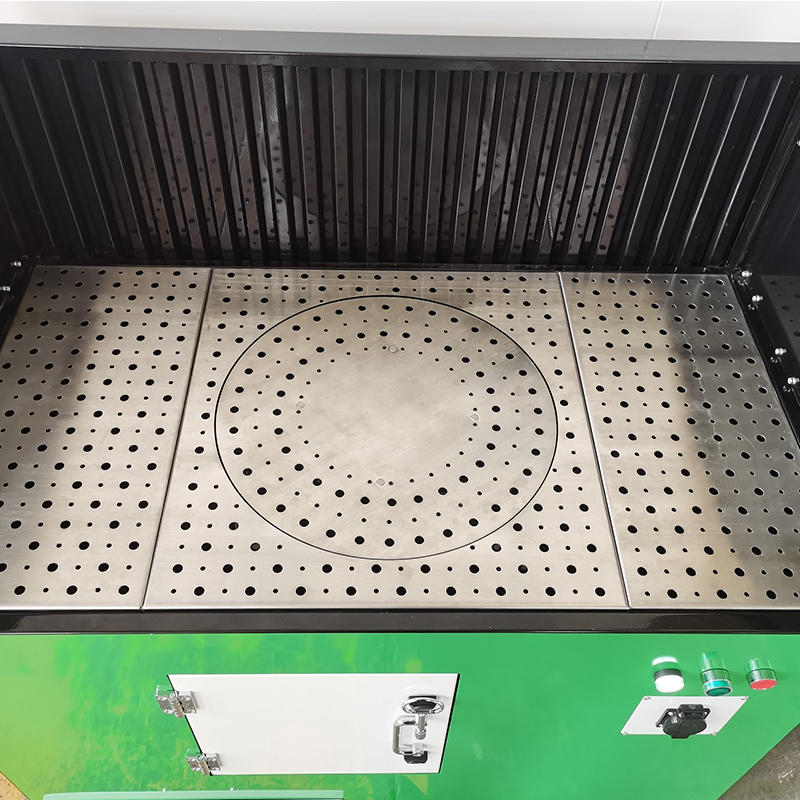

In summary, due to the particularity of the grinding process, the most effective dust removal method of the grinding workshop must be configured with a special Grinding Downdraft Table . Moland grinding and Polishing Downdraft Tables, putting the Industrial Dust Collector and the operation platform into one, not only convenient for grinding operations, but also synchronous efficient dust adsorption purification, can effectively capture the fine dust at the generation point.

Different from the general Grinding And Polishing Dust Collector, this Grinding Downdraft Table has a vertical suction hole in the structure, which can timely collect the dust generated during the grinding process, and the effective adsorption rate of the smoke can reach 99.9%.

Moland provides Mobile Fume Extractors , Industrial Dust Collectors, CNC Cutting Smoke Extractors, Laser Marking Fume Extractors, Polishing Downdraft Tables, Welding Fume Exhaust System, Cnc Cutting Fume Extraction Systems, etc.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.