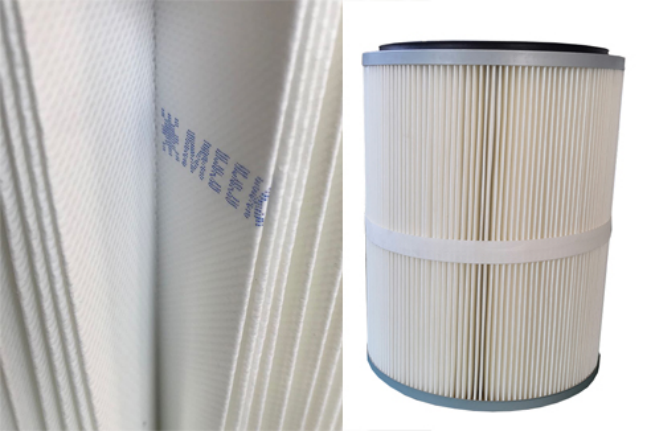

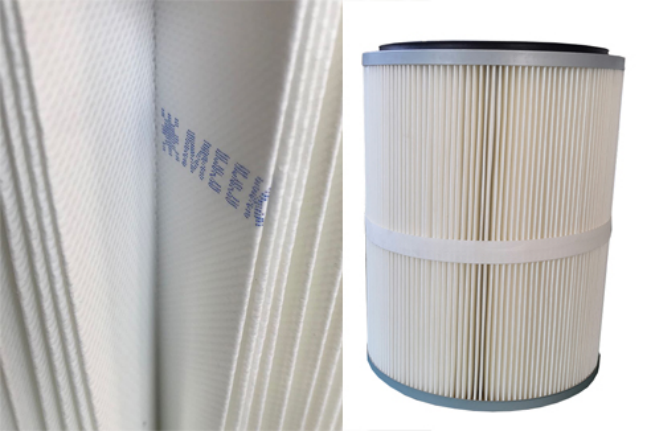

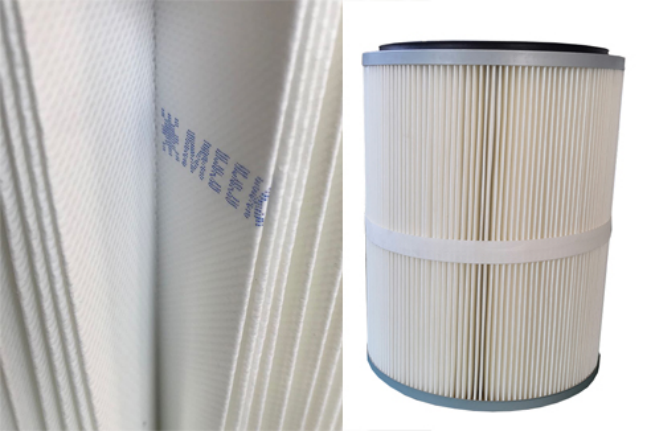

En las operaciones industriales, un colector de polvo eficaz es fundamental para mantener los lugares de trabajo limpios y seguros. Entre sus componentes clave, los materiales filtrantes desempeñan un papel decisivo en el rendimiento. Recubrimiento de PTFE y Nanofiltro son dos opciones líderes, cada una con ventajas únicas. En esta guía, compararemos estos materiales para que pueda elegir el más adecuado para su colector de polvo industrial.

Los filtros con revestimiento de PTFE son excelentes para soportar altas temperaturas. Por ejemplo, en fundiciones u operaciones de soldadura a alta temperatura, donde el polvo y los humos alcanzan niveles abrasadores, estos filtros resisten. A menudo pueden soportar temperaturas de hasta 260 °C sin descomponerse. Esto los convierte en la mejor elección para colectores de polvo en entornos industriales calurosos.

El revestimiento liso de PTFE crea una superficie de baja energía, por lo que las partículas de polvo no se adhieren con fuerza. Cuando se combina con sistemas de limpieza como la tecnología de chorro pulsante en un colector de polvo industrial, la eliminación del polvo se realiza sin esfuerzo. Como resultado, los filtros duran más y mantienen un rendimiento constante a lo largo del tiempo.

Los filtros con revestimiento de PTFE ofrecen resultados de filtración sólidos. Capturan partículas de hasta 0,3μm con altos índices de eliminación, lo que resulta esencial para mantener limpio el aire industrial y cumplir las normas de seguridad.

Los nanofiltros están compuestos por fibras ultrafinas, lo que les confiere una ventaja en la captura de partículas submicrónicas, incluso mejor que las opciones con revestimiento de PTFE. En industrias como la farmacéutica o la microelectrónica, donde es necesario eliminar el polvo diminuto, estos filtros de un colector de polvo industrial tienen un rendimiento excepcional.

Gracias a su estructura única, los Nanofiltros tienen una menor caída de presión. Esto significa que el colector de polvo no tiene que trabajar tanto para hacer pasar el aire, lo que reduce el consumo de energía.

Sin embargo, los nanofiltros tienen dificultades con el calor elevado. Son más sensibles a la temperatura que los filtros recubiertos de PTFE y pueden degradarse a niveles relativamente bajos. Por esta razón, no son ideales para procesos industriales de alta temperatura.

A la hora de decidir entre un filtro con revestimiento de PTFE y un filtro Nano para su colector de polvo, comience por evaluar su entorno de trabajo. Si sus operaciones implican altas temperaturas, como la metalurgia o la fabricación de vidrio, los filtros con revestimiento de PTFE son la apuesta más segura. Por otro lado, si necesita atrapar partículas ultrafinas y priorizar la eficiencia energética en entornos más fríos (como laboratorios o plantas electrónicas), el filtro Nano le servirá mejor.

Además, hay que tener en cuenta el mantenimiento a largo plazo. Los filtros con revestimiento de PTFE pueden tener costes iniciales más elevados, pero duran más en condiciones duras, mientras que el filtro Nano podría ahorrar en facturas de energía con el tiempo. Si sopesa estos factores, se asegurará de que su colector de polvo industrial funcione con la máxima eficiencia.

Los materiales de los filtros PTFE y Nano aportan ventajas distintas a los colectores de polvo. Las opciones con revestimiento de PTFE prosperan a altas temperaturas y son fáciles de mantener, mientras que el filtro Nano destaca en la captura de partículas finas y la eficiencia energética. Al adaptar el filtro a sus necesidades industriales específicas, mejorará el rendimiento de su aspirador y creará un espacio de trabajo más saludable y seguro.