The welding workshop of construction machinery, fixture and other large, heterogeneous workpieces has a huge span, and the workshop is long, and the welding station is not fixed; the workpieces are hoisted by crane.

The dust removal system shall not affect the production efficiency. Considering that the welding station is not fixed and the workpiece is relatively large, the dust removal method shall not affect the workpiece hoisting and the worker's production efficiency,

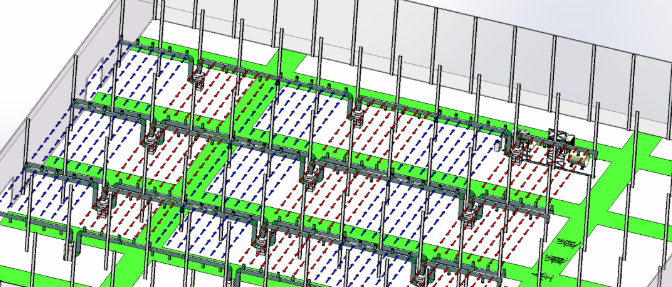

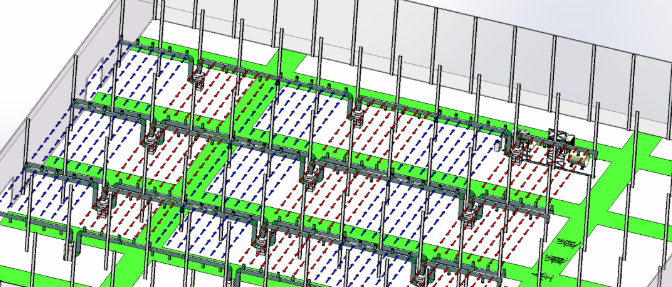

Therefore, we suggest to adopt the blowing suction centralized dust removal mode, which is based on the user's needs and the design principle of meeting the production process requirements,

It is mainly considered from the working environment, atmospheric emission standard, reliable operation of equipment, convenient operation and maintenance, etc,

Try our best to provide the best and most economical dust control scheme.

Introduction to the purification principle of the blowing and suction system:

The smoke-blowing dust purifier is equipped with air duct return air outlets and air supply outlets, and its return air outlet distribution and laying position are located at the dense height of smoke and dust gathering (4-7 meters, the height of the welding point is different, and the height of the dust density is also different).

After filtering and meeting the indoor circulation standard, the air inlet and exhaust pipes reach the air supply outlet, and are sent to the smoke and dust purification system that continuously circulates at the same floor height---the blowing smoke dust purification system.

The collection of harmful smoke and dust in dense areas of the same height is highly efficient; the use of high-efficiency filters, the filtration accuracy fully meets the indoor emission standards, and the filtration efficiency reaches 99.9%, which effectively improves the working area environment;

Because the collection of smoke and dust is not directly aimed at the smoke-producing part, the dust removal system is not affected by the size of the welding workpiece, and is not affected by the change of the welding station; completely solve the problem of dust purification and will not cause secondary pollution to the atmosphere;

The two devices are used together to form a perfect blowing and suction purification system, the required air volume is only half of the traditional mixed air supply form, and the operating energy consumption is greatly reduced;

Because the smoke and dust can reach the indoor emission standard after filtering, the indoor air can be circulated to avoid the waste of indoor cold/heat energy caused by external exhaust;

The dust removal system is not affected by the operator's habits, and the operator is not affected by any interference from the dust removal system during the work process, which can greatly improve production efficiency