Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1. Hazards of plasma cutting smoke

Plasma cutting machine in the process of cutting metal will produce a lot of smoke and dust, such as: metal oxides, sulfides, hydrocarbons and so on. These fumes fly in the air and are easy to inhale into the lungs, which is harmful to the health of workers and the entire factory environment, may lead to the emergence of many occupational diseases, and smoke will also affect the service life of other equipment.

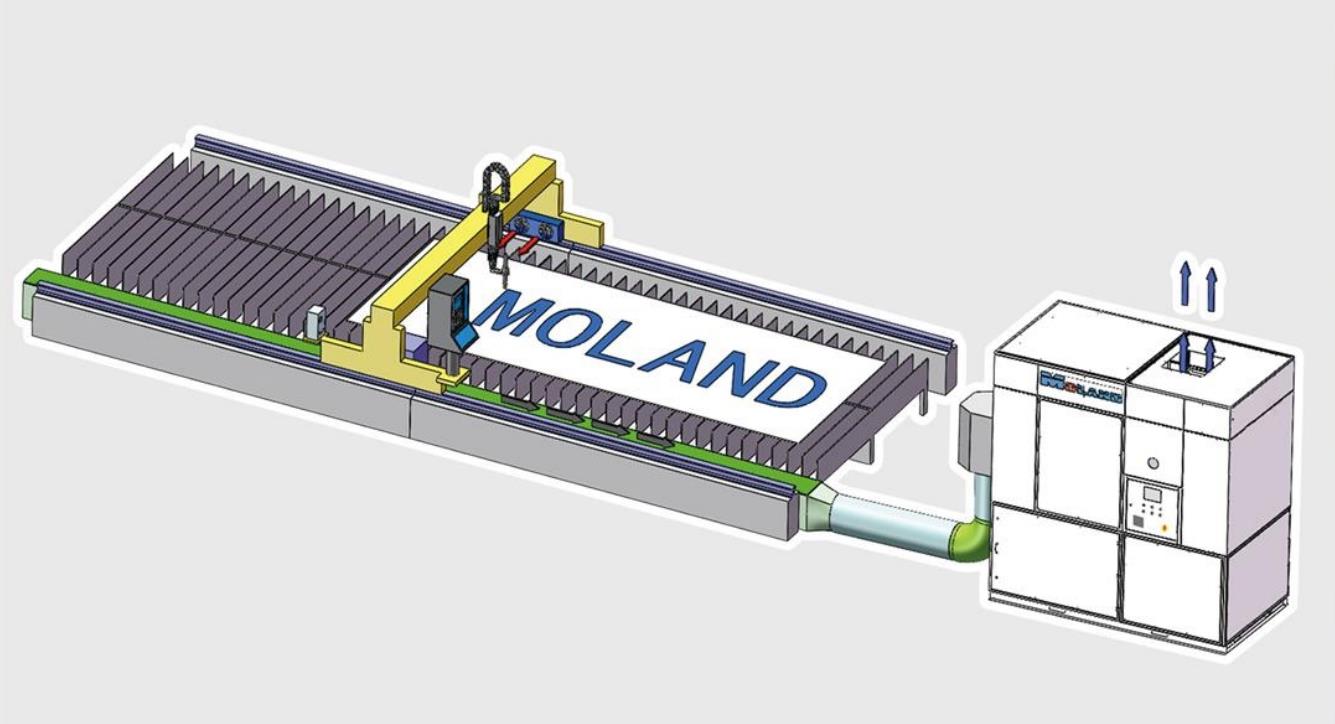

Industrial Dust Collectors for plasma cutting fume extraction

A set of Cnc Cutting Smoke Extractor is installed on the plasma cutting work table, and the collected dust containing gas is directly transported to the main machine of the Industrial Dust Collector for treatment and then directly discharged to the outside or into the room for recycling. We produce Plasma Cutting Dust Collector using a very efficient filter cylinder Dust Collector host, with side suction dust collection method treatment, for you to solve the problem of plasma cutting dust.

2. Plasma laser cutting machine Industrial Dust Collector working principle

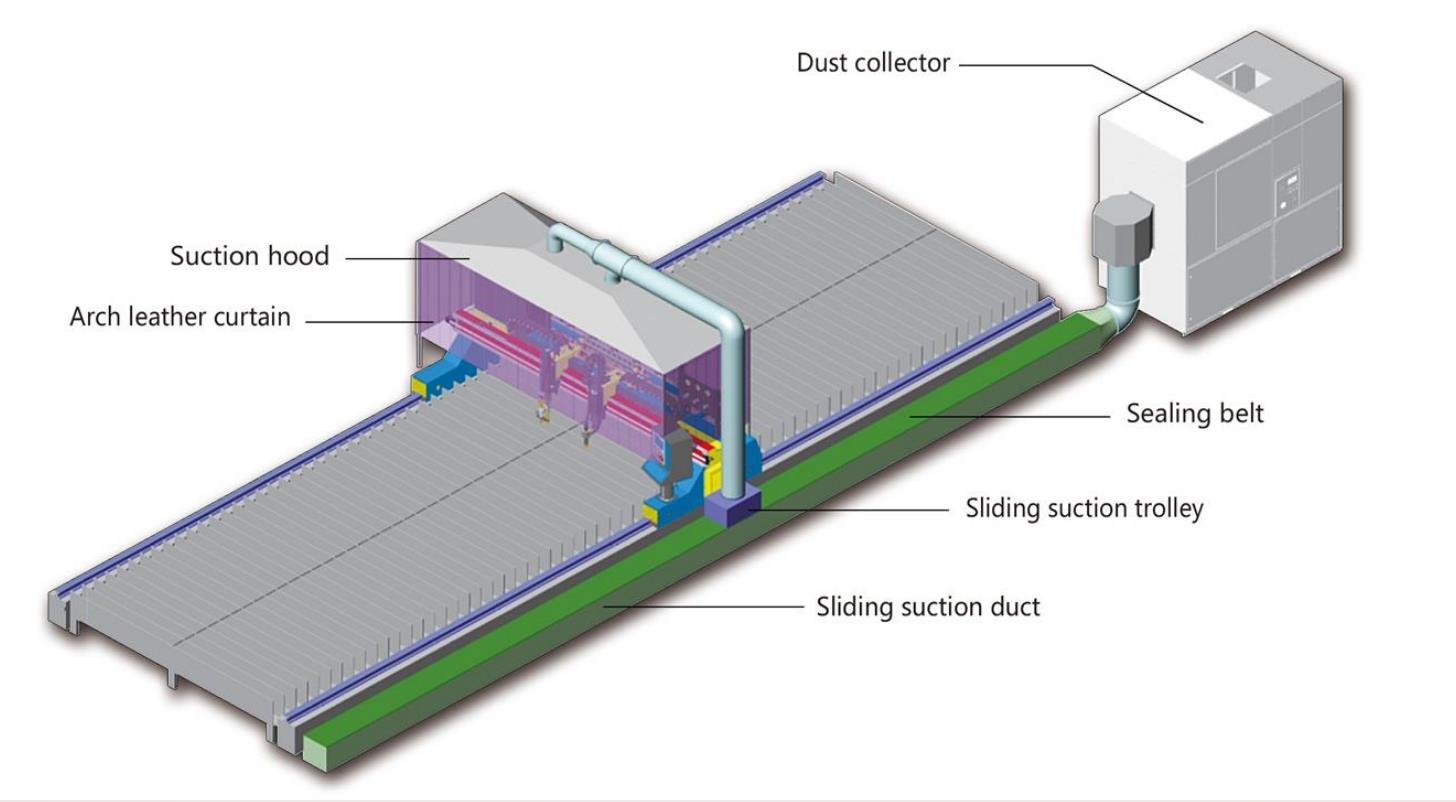

A sliding suction duct is placed on one side of the cutting platform, which has a suction duct that can move with the cutting machine. The blower is fixed on the cutting machine and is kept in line with the cutting head. The lower part of the cutting platform is a grating with a vertical plate, which forms a sealed air duct with the cutting plate, and always maintains air pumping only within the limited width of the cutting, that is, the part that produces smoke. When working, the sealing belt is tightly attached to the square suction duct under the action of negative pressure of the pipeline to play a sealing role. There are two rollers in the sliding suction trolley. The sealed belt is jacked up here, so that the dust enters the square air duct through the suction of the sliding suction car, and finally inhales the filter cartridge and the main engine of the purifier.

3. Plasma laser cutting machine Industrial Dust Collector structure

Dust collector host, dust filter cartridge, solenoid valve, pulse controller, drainage nozzle, dust bucket, sliding suction duct, suction car. According to the design needs, it can also be equipped with electric control box, fan, explosion vent, differential pressure gauge, frequency conversion fan, frequency converter, electric discharger, plug valve, silencer, flame retardant, pressure regulator and so on.

4. Benefits of the above fume extraction solution

4.1 The efficiency of dry cutting is greatly improved compared with cutting on water.

4.2 The exhaust pipe takes away most of the heat in the cutting process, which has a great protective effect on the cutting head and improves its service life.

4.3 There is no moisture and smoke in the upper part of the steel plate during the cutting process, making the cutting more accurate and precise.

4.4 Worker safety is greatly increased when cutting aluminum, magnesium and other oxides and water are prone to explosion.

4.5 Dry dust removal reduces secondary pollution compared with wet method, and cutting slag is easy to clean up.

4.6 The working grid plate is detachable, which is convenient for cleaning, maintenance and changing the grid plate.

5. The Selection of Industrial Dust Collector

5.1 The purification of dust can only be achieved by the dust collector, and the selection of the dust collector directly affects the collection effect of the dust removal system, the dust removal power consumption, and the long-term stable and reliable operation of the entire system. There are many forms of dust collector, each has advantages and disadvantages, the key is how to develop strengths and avoid weaknesses, and adapt to the system process and dust composition, in order to obtain better treatment effect.

5.2 MLWF series filter pulse jet cleaning dust collector is a set of years of research and technical experience and results, launched to users with an international level of filter pulse dust collector technology and products. It is a dust removal equipment with good dust removal effect, high dust removal efficiency, reliable operation and easy maintenance.

5.3 Control system The control system can be manual, automatic two ways, humanized design of pulse clearance mechanism, PLC control cabinet independent filter cleaning, dust unloading work, simple operation.

6. Industrial Dust Collector working principle

The dust collector is mainly composed of the fan room, pulse jet room, Cartridge Filter room and the dust hopper room. The dust-containing air enters the dust hopper from the inlet air duct of the dust collector, the large particles of dust are separated and fall directly into the dust hopper, while the finer dust evenly enters the central box and is adsorbed on the outer surface of the Cartridge Filters, and the clean gas enters the upper box through the filter and is discharged into the atmosphere through the air outlet. With the progress of filtration conditions, the dust on the filter accumulates more and more. When the equipment resistance reaches the limited resistance value, the cleaning control device will set the differential pressure setting value or the cleaning time setting value, and the cleaning fan will be opened according to the setting procedure to clean the dust, and the dust on the filter will be removed (even if the fine dust can be cleaned more thoroughly) into the dust hopper. It is discharged by the exhaust mechanism.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.