Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The harm caused by industrial dust is many aspects, dust on the human body, workshop ecological environment, equipment, production process, product quality, economic income, biodiversity and other aspects have adverse effects. Therefore, we should pay attention to the treatment of industrial dust and pay attention to the choice of Industrial Dust Collectors.

Here, we introduce you Moland movable Industrial Dust Collectors, also called Mobile Fume Extractors.

Mobile Fume Extractors are suitable for single-station double-station welding, cutting, grinding and other operating station dust and dust control, the main features are: small size, small footprint, suitable for compact space. The Mobile Fume Extractors are equipped with casters, easy to move; equipped with a 2 or 3-meter Flexible Suction Arm, it can hover freely.

Moland supplies economical Mobile Fume Extractors and automatic pulse jet cleaning Mobile Fume Extractors (Industrial Dust Collectors).

The economical mobile fume extractor has no pule jet cleaning device and is mainly used in places where the welding dust removal or dust amount is relatively small.

The automatic pulse jet cleaning Mobile Fume Extractors are equipped with sufficient filtration area flame retardant film coated Cartridge Filter, so as to ensure the service time and filtration accuracy of the cartridge filter, especially for occasions with large amounts of dust.

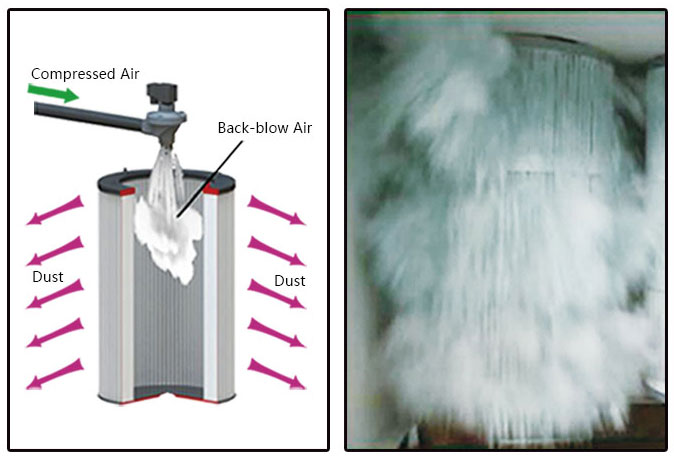

Pulse jet cleaning principle

The pulse jet cleaning system is composed of air storage tanks, solenoid valves, PLC controller, and compressed air. One end of the pulse valve is connected to the compressed air storage tank, and the other end is connected to the injection pipe. An exhaust valve is installed on the valve cover, and the exhaust valve is controlled by a PLC controller.

When there is no signal from the PLC controller, the movable baffle of the exhaust valve is in the position to close the exhaust hole; when the program controller sends a signal, the movable baffle is opened, and the compressed air of the storage tank is quickly released, so the inner corrugated membrane of the exhaust valve is pressed in the opposite direction, the jet opening is opened, and the compressed air enters the cartridge filter through the pulse valve for blowing and cleaning. When the signal disappears, the movable baffle returns to the original position of closing the exhaust valve, and the corrugated membrane closes the jet mouth, blowing stops automatically.

The dust cleaning is completed in about 0.1-0.3S each time, and it is the high-pressure air ejected at this moment that has a good dust removal effect. The air enters the cartridge filter at a high flow rate, causing the cartridge filter to expand rapidly, causing a shock and vibration, so that the dust attached to the cartridge filter is shaken off, and the fine dust adsorbed on the surface of the cartridge filter is shaken off into the dust collecting bucket under the action of the airflow. The air pressure of pulse injection is 0.4~0.6MPa, and the constant air supply must be maintained during operation.

Welcome to contact us for more information.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.