Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The hazards of dust generated by grinding and polishing

Cutting and grinding are indispensable industrial technical means in the mechanical processing industry and play an important role in economic construction. The dust generated during the grinding and polishing process causes great harm to the health of workers, and the grinding of some aluminum-magnesium alloys can produce flammable and explosive dust, which poses a major safety hazard.

Whether it is common manual cutting/grinding, or grinding wheel cutting/polishing, or even the increasingly popular robot grinding and polishing, a certain amount of grinding dust will inevitably be produced. If it is not treated promptly and effectively, it will pollute the working environment. Damage to workers' health and even risk of explosion.

As people pay more and more attention to occupational health, and governments and industry organizations are strengthening regulations, it will become more and more common for grinding operations to be equipped with Industrial Dust Collectors.

How to control grinding dust?

1. Choose the grinding Industrial Dust Collectors well

From the perspective of the cutting and grinding Industrial Dust Collectors, it requires large suction power, flame retardancy, and high filtration accuracy. A Cartridge Filter Industrial Dust Collector that meets these three basic conditions has the obvious characteristics of small footprint and high filtration accuracy. , the most critical thing is the selection of filter materials. According to Moland`s many years of industry experience, the selection of filter materials for grinding dust must generally have the following characteristics:

1.1 Filtration accuracy: the filtration efficiency for dust particles of 0.3µm is over 99%.

1.2 Has flame retardant properties.

1.3 The equipment has pulse backflush function.

1.4 For flammable and explosive dust, anti-static and explosion-proof measures must be perfected.

2. The capture method must be reliable

From the perspective of grinding capture methods, we have always recommended using the source capture method to deal with grinding smoke, because this is the most economical, most reliable, and has the best effect. However, in reality, some large workpieces, large steel structure workshops, In working conditions such as multi-station non-fixed grinding and polishing, it is not realistic to capture the source. Some will greatly reduce the work efficiency of workers, and some will interfere with their work routes.

Therefore, the way to capture polishing dust needs to take into account the on-site process route, solder joint layout, workstation characteristics and work efficiency, and communicate the most suitable treatment method for the owner's current working conditions. Currently, the commonly used capture methods are as follows:

2.1 Integrated grinding Polishing Downdraft Tables

2.2 Split sanding table

2.3 Environmentally friendly grinder

2.4 Equipment matching

2.5 Telescopic Grinding Room, Stationary Grinding Room with Grinding Dust Collector

2.6 Blowing and suction type overall workshop purification system

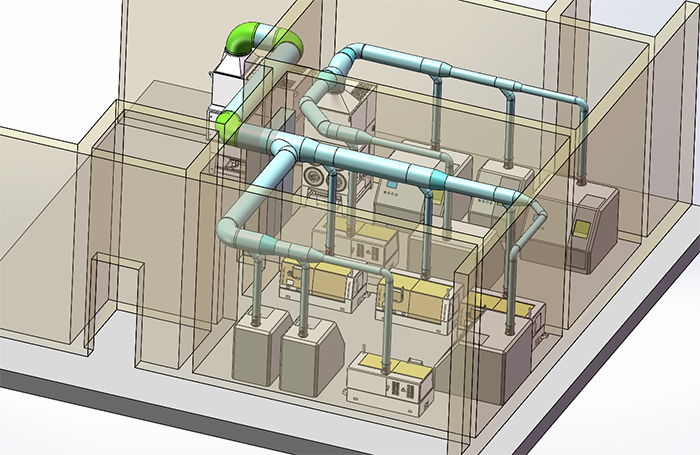

2.7 Central dust collection system [equipped with side suction/bottom suction/top suction collection hood

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.