Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Be wary of dust explosions and choosing the right explosion-proof Dust Collector is key!

Industrial production is the main cause of dust generation. When dust reaches a sufficient concentration within a certain range, if it encounters a fire source, it will cause an explosion with disastrous consequences.

In order to avoid the occurrence of such problems, reasonable and feasible explosion-proof measures must be taken to improve the safety of dust explosion hazardous places and fundamentally reduce or even eliminate the occurrence of dust explosions.

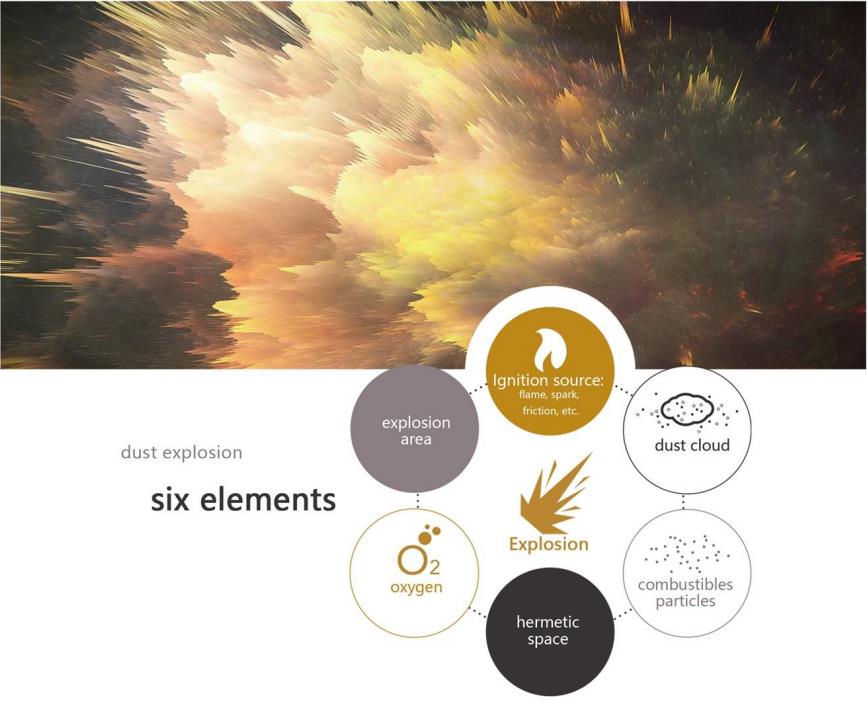

To prevent dust explosions, you must first know how dust explosions occur. Dust combustion will only cause an explosion when certain conditions are reached. The basic conditions include:

First: it must be combustible dust;

Second: there must be sufficient oxygen content (air or oxygen);

Third: Combustible dust is fully mixed with air or oxygen to form dispersed dust;

Fourth: The dust content reaches explosive concentration;

Fifth: There is an ignition source with minimum energy to ignite combustible dust. In addition, dust explosions also have certain requirements on space range, air pressure and temperature.

In other words, if the above conditions are not met, the dust will not explode. So we have a direction for the prevention of dust explosions.

How to prevent "dust explosion"?

01 Eliminate ignition sources

①Reliable grounding;

② Use dust explosion-proof electrical appliances;

③Spark detection and extinguishing;

④ Eliminate open flames;

⑤Prevent local overheating;

⑥Do not hit with metal to prevent sparks.

02 Eliminate flammable materials

①Keep the workspace tidy and clean properly;

②The surface of the equipment is clean and there is no accumulation of dust;

③Improve process equipment and eliminate the root causes of dust accumulation in equipment.

03 Eliminate oxidants

①Internal air inerting;

②Replace oxygen with inert gases such as nitrogen, carbon dioxide, etc.

04Improve protection measures

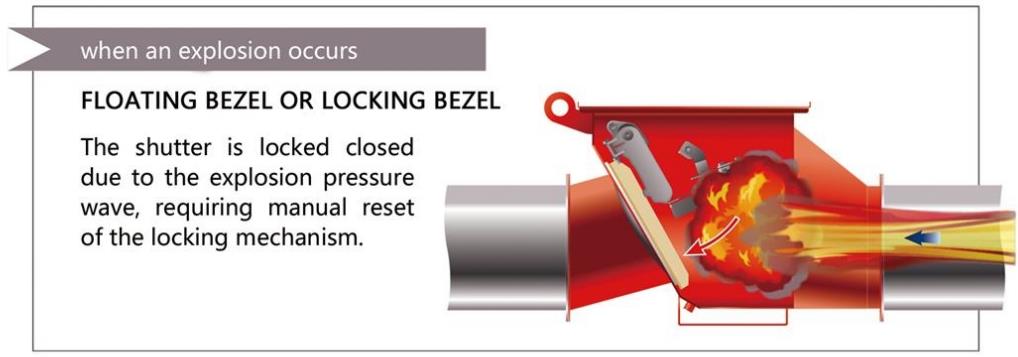

① Vent explosion;

② Explosion suppression;

③Explosion proof;

④Improve the pressure resistance of the equipment;

⑤Use multiple protection schemes together.

05Ventilation and dust removal

Install a relatively independent ventilation and dust removal system and set up a grounding device. The prevention method usually adopted by Industrial Dust Collectors is to avoid ignition sources as much as possible.

Reduce the possibility of ignition sources by adopting measures such as antistatic filter materials, complete machine grounding, explosion-proof fans, and explosion-proof electronic controls. Explosion vents should be installed on ventilation ducts.

At the same time, methods such as dust hoppers and active dust cleaning are used to reduce dust accumulation and avoid the appearance of dust clouds.

Preventive measures are to prevent the occurrence of explosive factors from the source as much as possible. However, in real life, the ubiquitous potential ignition sources make this task difficult to complete 100%.

Preventive measures can only reduce the probability of explosions but cannot completely prevent them. Therefore, in addition to preventive measures, we must also consider hazard control when explosions occur.

Explosion control

Industrial Dust Collectors are usually used to capture and filter all kinds of dust generated during the production process. Therefore, dust will be concentrated inside the Industrial Dust Collectors. For dust with explosion hazards, the risk of explosion in the dust collector will be higher.

Once an explosion occurs, we need to have corresponding protective measures to minimize the damage caused by the explosion and protect the enterprise from the impact of the explosion to ensure the safety of employees and the rapid recovery of production.

We will provide our dust removal equipment with explosion-proof discs, explosion-proof valves and flameless explosion-proof devices provided by professional explosion-proof product manufacturers. The explosion-proof calculations are all carried out by our company entrusted by the manufacturer to obtain compliance. Standard applicable products.

These related products can provide ATEX explosion-proof certification.

Explosion-proof type Industrial Dust Collectors

01 It is safer to use an explosion-proof electric control box. The explosion-proof electric control box is equipped with a PLC intelligent control system, which can independently adjust various parameters of the dust removal host according to different working conditions and monitor the operating status in real time.

02 The imported film-coated Anti Static Filter is made of conductive carbon fiber blend to achieve conductive properties. It is not easy to burn after special flame-retardant treatment and has a high fire protection level.

03 Explosion-proof fan is suitable for environments with temperature groups T1~T4; the impeller is made of aluminum alloy to prevent sparks during operation, and the motor adopts an explosion-proof motor.

04 Flameless relief device effectively prevents flames from erupting, safely releases pressure, and avoids dust explosion or fire accidents caused by flames.

05 Explosion-proof wind speed transmitter: accurately detects wind speed and volume deep into the pipeline, and provides real-time feedback on the PLC smart display.

06 Fire prevention and fire extinguishing protection measures for dust removal systems

The dust collector can be equipped with a CO2 fire extinguisher. The flame detection device installed in the dust collector can quickly extinguish the flames in the dust collector and minimize losses.

A spark detection device can be installed on the air inlet duct of the Industrial Fume Extractor Dust Collector. If a spark is found, immediately control the fire extinguisher to extinguish the sparks in the Dust Collector and prevent the dust from burning.

Explosion-proof cartridge Dust Collector is suitable for places with explosion-proof requirements, such as medicine, sandblasting, powder spraying, lithium batteries, food, engraving, 3D printing, casting, grinding and polishing, mixing, crushing, powder transportation, powder feeding, and powder loading. Dust removal in working conditions such as bags, welding and cutting, etc., is mostly used for the collection and management of floating and suspended dust. It can be used for centralized dust removal at a single station or multiple stations

Moland can comprehensively use a variety of industrial dust control methods based on the characteristics of the customer's industry to tailor more professional, efficient and targeted industrial dust control solutions for customers.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.