Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Moland i committed to the central industrial dust collection and purification of the entire workshop, including the dust generated by cutting, welding, grinding and other production progress.

There are four kinds of centralized dust purification systems independently developed by Moland: cantilever centralized dust removal system, hood suction centralized dust removal system, room centralized dust removal system and blow suction centralized dust removal system.

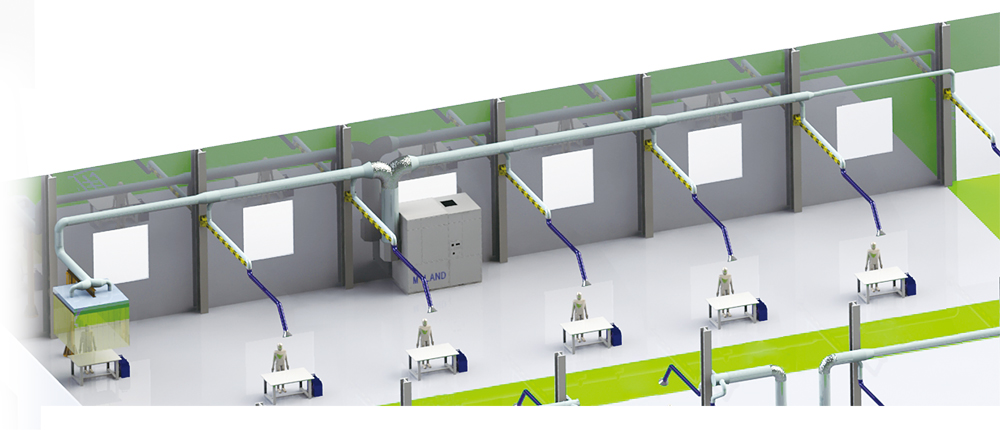

1. Cantilever centralized dust removal system

Cantilever type dust and smoke removal system is suitable for manual welding conditions with uniform distribution of stations and small span.

The cantilever type welding dust and smoke removal system can make the dust and smoke generated by each welding station be effectively absorbed at the generating point. The Extraction Arms can flexibly rotate 360°, hover at will, and adjust the position of the suction cover arbitrarily according to the welding point. The strong suction can capture smoke and dust from the source, and the purification efficiency is as high as 99.9%.

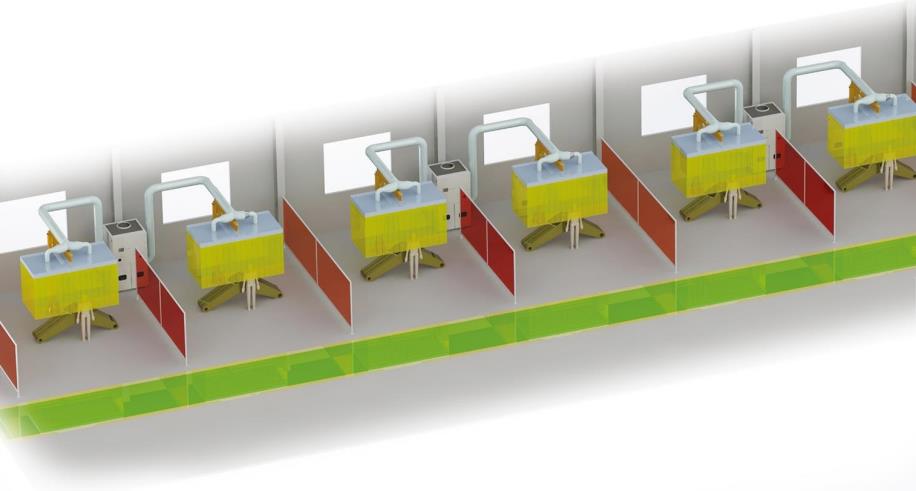

2. Hood suction centralized dust removal system

The Extraction Arms can flexibly rotate 360°, hover at will, and adjust the position of the suction cover arbitrarily according to the welding point. The strong suction can capture smoke and dust from the source, and the purification efficiency is as high as 99.9%.

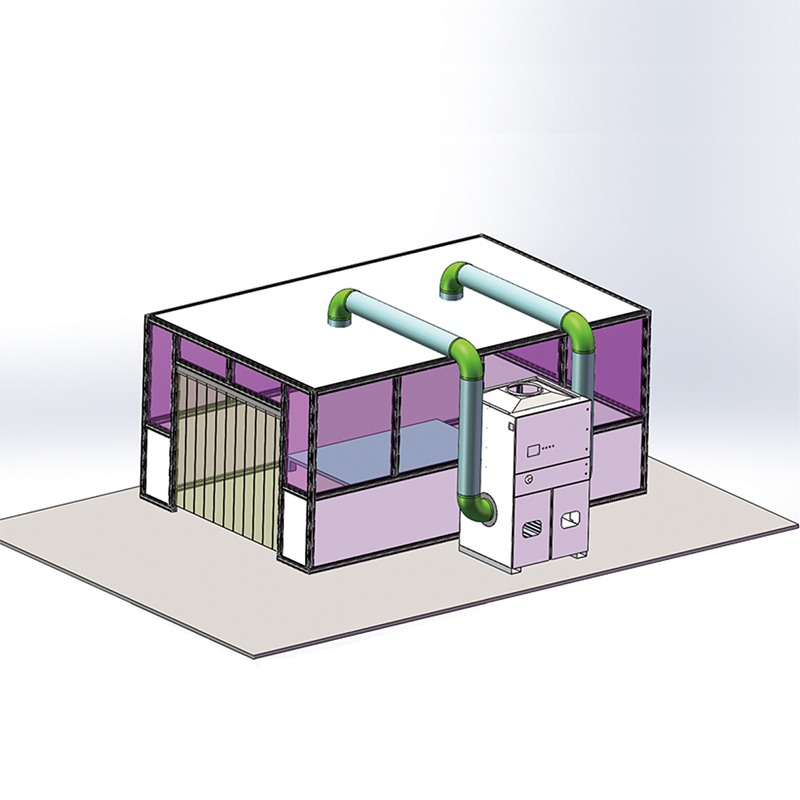

3. Room centralized dust removal system

This welding dust and Smoke Exhaust System is mainly used for robot welding. The welding station is fixed. The room is with top suction ports, so that the welding fume and smoke and controlled within room and extracted out from Industrial Dust Collector.

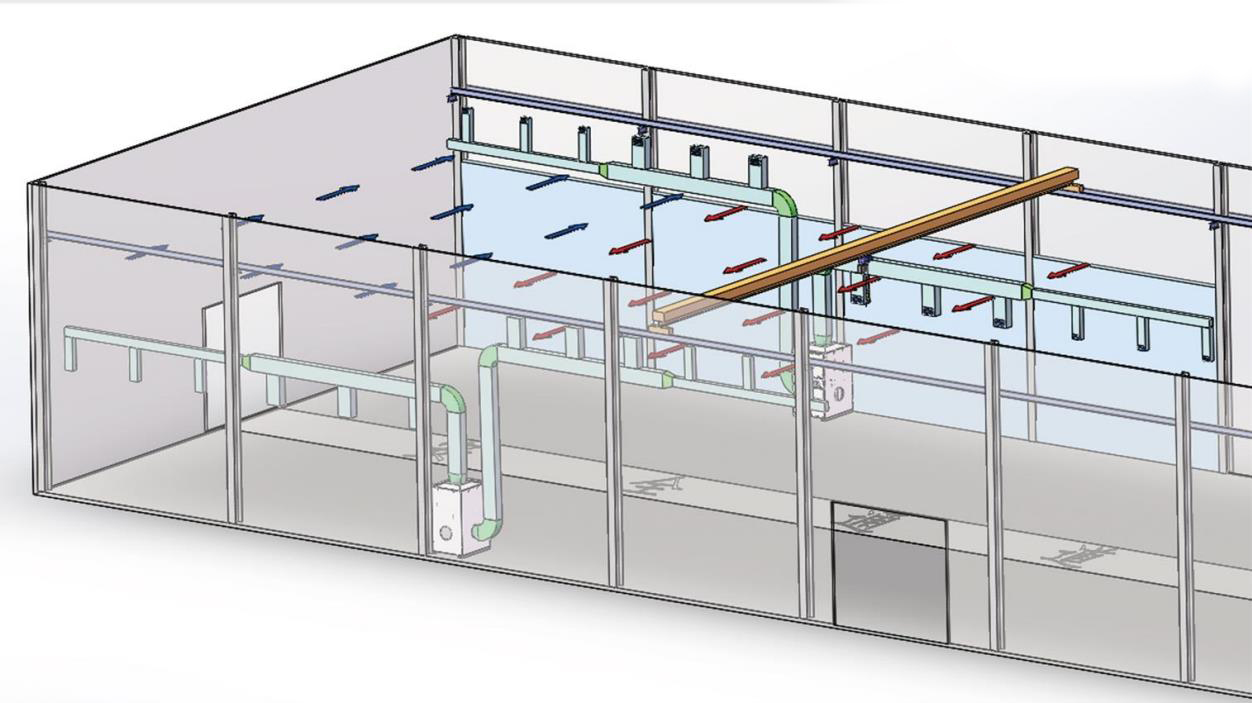

4. Blow suction centralized dust removal system

For working conditions in workshops with many welding stations, large spans, and scattered solder joints, the Blow-suction Fume Extraction System can be selected. By rationally distributing the air blowing port and the air suction port, an effect similar to the overall air exchange in the workshop is achieved, that is, the exhaust smoke and dust are blown to the side of the suction port through the air blowing port, and the smoke and dust are sucked away by the suction port, and then reach the dust removal host through the pipeline through high-efficiency filtration and purification to meet the standard emission.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.