Cartridge dust collectors are important equipment used to capture and remove fume and dust matter generated in industrial production. Its performance directly impacts the environmental quality and production efficiency of industrial processes. The dust removal efficiency is one of the key indicators for evaluating dust collector performance.

The choice of dust removal method directly affects the dust removal efficiency, resistance, energy consumption, and service life of the cartridge dust collector. Today, let's introduce the advantages of two cleaning methods for cartridge dust collectors: pulse jet cleaning and rotor backblow cleaning!

Although it consumes compressed air, the superior cleaning effect reduces the frequency of cleaning and downtime, resulting in lower overall energy consumption. Furthermore, the pulse jet cleaning system, combined with PLC and other control systems, can automatically adjust cleaning parameters based on operating conditions, optimizing energy consumption.

The high-pressure gas instantaneous jet cleaning method minimizes impact on the filter cartridge, avoiding damage and wear caused by mechanical vibration. At the same time, extending filters lifespan, and reducing replacement costs and maintenance workload. The structural design of the pulse jet dust collector also makes filter inspection and replacement convenient.

During the cleaning process, dust falls directly into the dust collection drawer, eliminating the risk of escape and effectively preventing secondary pollution.

Compared to pulse jet cleaning, it completes the cleaning operation in a shorter time, making it more suitable for scenarios requiring rapid equipment performance recovery and handling large amounts of dust.

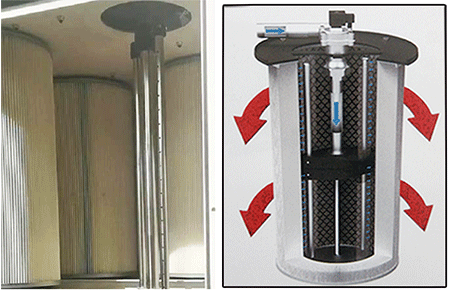

Components such as the rotary blades are precision-machined from stainless steel tubing, and supported by two sealed bearing devices, making the structure robust. The robust structure allows for natural rotation under high-pressure airflow, resulting in high operational stability and lower maintenance rates. This reduces downtime and maintenance costs due to cleaning component failures.

Pulse jet cleaning excels in cleaning performance, ensuring long-term stable operation. Its high-efficiency cleaning capability effectively prevents filter clogging, guaranteeing stable dust removal efficiency, which is crucial for dust removal systems requiring continuous and stable operation in industrial production.

Its broad adaptability to various filter materials and dust characteristics allows it to perform well in different industrial fields and production environments. It eliminates the need for frequent replacement of cleaning equipment or adjustment of cleaning methods, reducing equipment investment and operating costs.

By combining with an automated control system, pulse cleaning can achieve optimized energy consumption management, reducing energy consumption while ensuring cleaning effect, which is in line with the development trend of energy saving and environmental protection in modern industry.