Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Scope of application:

The welding workshop, the size of welding workpiece is uncertain, the welding position is not fixed, and there are many welding methods;

Working principle:

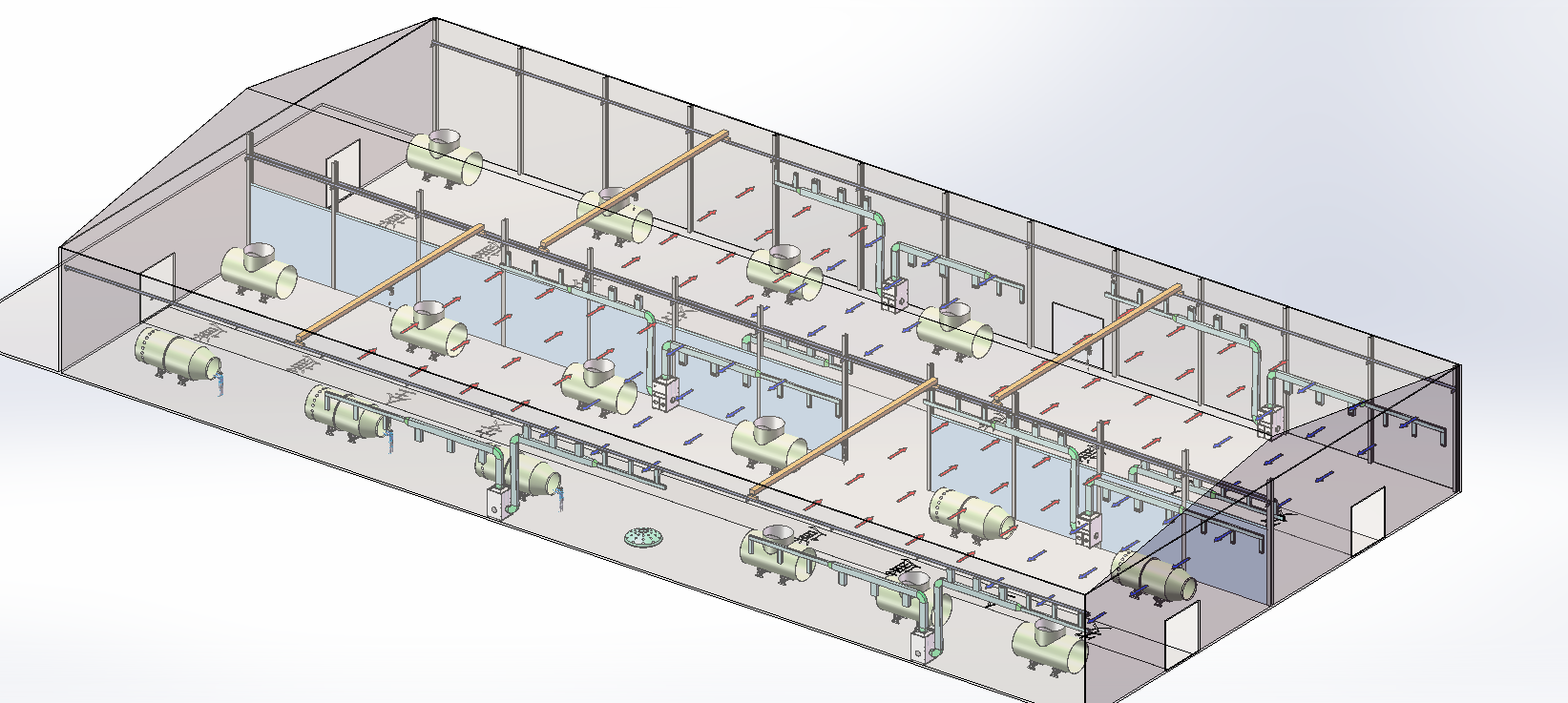

The principle of the whole ventilation displacement dust removal system

The integral ventilation displacement dust removal is to use the characteristics of welding fume suspended above 4-8 meters due to thermal rise and gravity. The suction pipe is installed on the column about 4-5 meters high on one side of the workshop. Two layers of air suction outlets are set on the pipeline. The wind power of the Dust Collector is used to effectively collect the dust floating on the upper part of the workshop. The air outlet is set on the dust removal pipe on the other side of the workshop, and the qualified air discharged by the dust collector is used as the air supply to speed up the air flow and make the welding dust flow to the suction outlet.

The centralized blowing and suction dust removal system in welding workshop is composed of dust collecting cover, pipeline, main engine, fan and smoke exhaust pipe. During operation, the suction generated by the fan will collect the workshop dust to the pipeline system through the dust collecting cover, and then the dust will be transported to the host machine for filtration and purification through the pipeline. The purified air will be directly discharged into the outdoor high altitude, which can reduce the damage to the surrounding air environment Because the dust air does not participate in the indoor air circulation, it can significantly improve the air quality in the workshop and reduce the interference of smoke and dust on human health.

The number of filter elements placed in the main machine of the welding blow suction dust collector in the workshop is determined in advance according to the amount of smoke and dust calculated according to the number of stations in the whole workshop. The required number of filter elements can be obtained by dividing the required total effective filtering area by the filtering area of a single filter element. In order to achieve the ideal dust removal and purification effect, the pipeline for transporting smoke and dust should avoid the traffic lane, reduce the elbow and reduce the wind resistance as far as possible. Scope of application: dust cleaning equipment for welding workshop, which can be used for multi station welding dust treatment, laser cutting, flame plasma cutting dust removal and grinding dust, such as grinding iron chips, stone, furniture dust, etc.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.