Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The gas collecting hood is a device to control the dust laden airflow and collect dust. It is an important part of the local ventilation and dust removal system. The function of the gas collecting hood is to collect the smoke and dust emitted from the dust source and lead it into the purification system to prevent it from spreading to the production workshop and the atmosphere and causing pollution. If the form and location are selected reasonably, the better dust removal effect can be obtained by using small exhaust air volume.

The proper design of the integrated cover directly affects the dust collection effect of the Dust Collector. The air collecting and dust collecting hood is a device for controlling dust laden air flow and collecting dust.

1. Electric rotating dust collecting hood

The cantilever can swing freely around the fixed column and hover in the range of 180 ° under the action of swing angle motor. In this system, the swing angle mechanism adopts gear meshing mode to transmit swing angle power, which has the advantages of high transmission efficiency, stable operation and long service life.

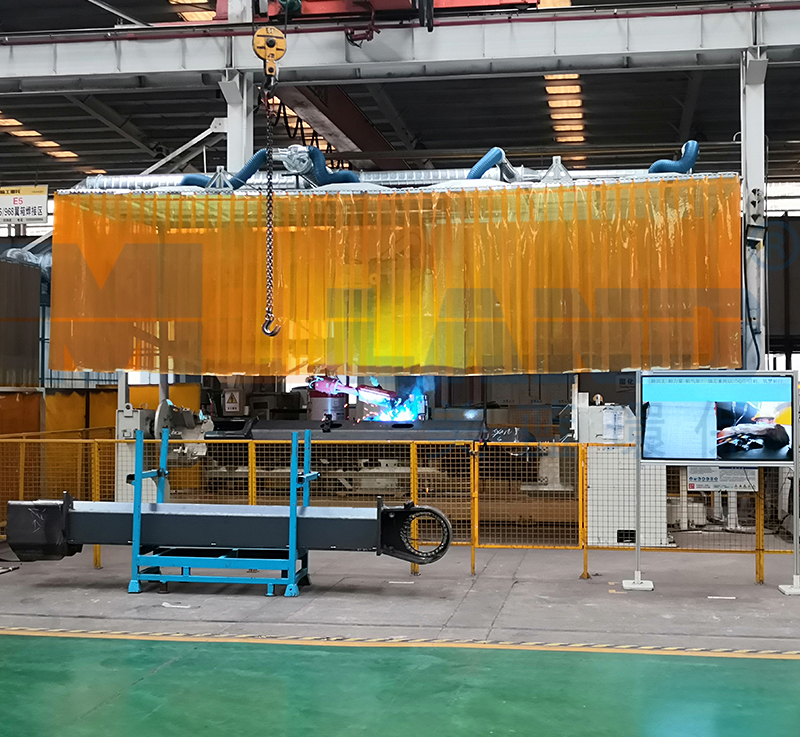

3. Fixed dust hood

The top Suction Hood is suitable for welding dust removal with fixed welding station. The shape of the top suction hood is quadrangle platform, and the included angle between each side and the ground is not less than 45 degrees. In order to avoid the interference of transverse air flow, arc curtain can be hung on the side of the suction hood. Workers can weld freely within the scope covered by the hood, and the smoke and dust generated can be captured and purified smoothly!

4. Manually rotate the dust hood

Compared with the electric rotating cover and the pneumatic translation cover, the manual rotating cover has lower cost and lower cost, which not only does not delay the traveling crane to get up and down the workpiece, but also reduces the air volume and investment.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.