According to the 《Air Pollution Prevention and Control Law》 and local regulations, enterprises are required to install purification equipment for centralized welding dust removal and treatment to prevent fugitive emissions from polluting the surrounding environment.

National emission standards require pollutant concentrations to be below specified limits. For example, particulate matter emissions must comply with the 《Integrated Emission Standard for Air Pollutants》 (GB 16297-1996). Welding fumes have small particle sizes (0.1-1 micrometers), and equipment such as cartridge fume extractors can achieve highly efficient purification (purification efficiency can reach over 99%).

In actual production, large welding workshops often contain many irregularly shaped and large parts, and welding points are not fixed. Point-to-point end-of-pipe collection by suction arms and dust collection hoods can severely affect workpiece hoisting and worker productivity. Distributed fume purification systems have emerged to address this challenge, balancing environmental compliance and production efficiency.

Distributed fume purification solutions are designed to address the multi-source, dispersed fume emissions in industrial production, achieving high-efficiency purification through regionalized treatment.

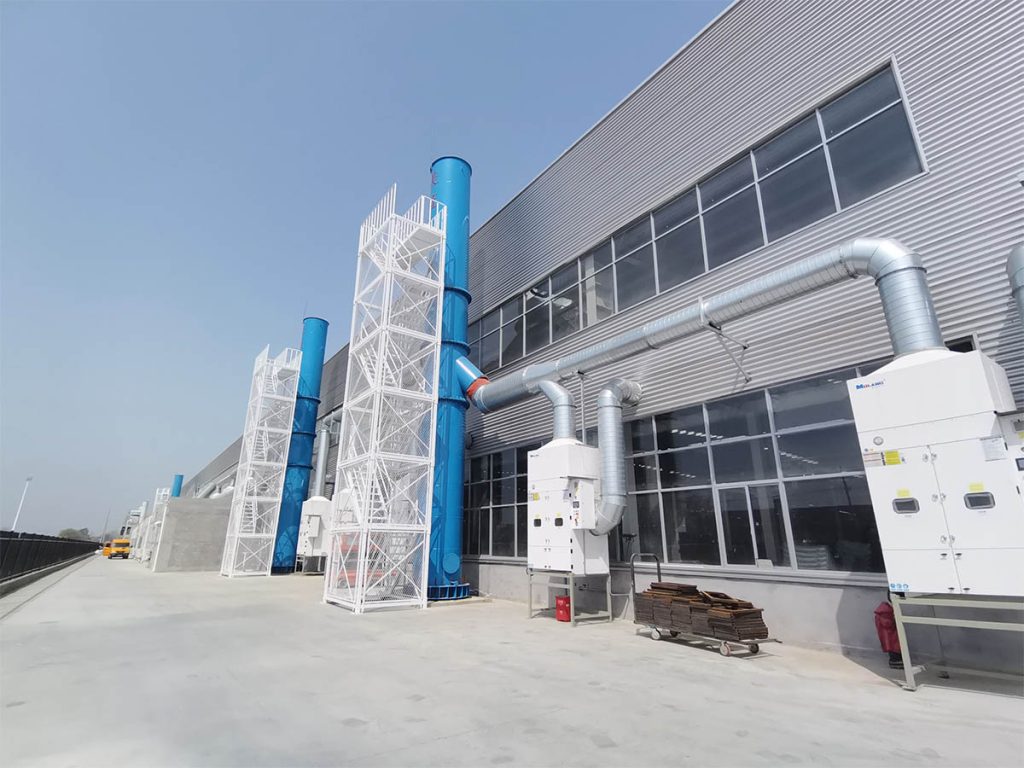

Suitable for large workshops (such as automobile manufacturing and shipbuilding), employing a combination of "negative pressure dust collection + high-efficiency filter cartridges" technology, achieving full workshop coverage with a purification efficiency of over 99%. The system connects each workstation via a pipeline network, laid out along the workshop columns, without affecting overhead crane operations. It eliminates the need for frequently swinging suction arms and dust collection hoods, which can impact worker productivity. A pulse jet cleaning device is used at the end to reduce dust concentration to below 4mg/m³.

The entire space is sized according to the required treatment area. Based on fluid simulation analysis, a reasonable air exchange rate is calculated for the entire space. The airflow direction is designed according to the workstation layout. For workshops requiring organized emissions, the design of the airflow vents can create a suspended fume airflow curtain. The final collection area can be connected to an outdoor chimney for organized emissions.

This approach not only solves the problem of traditional dust removal methods affecting production efficiency, but also complies with environmental protection regulations on organized emissions, making it a perfect solution.