In industrial production, welding fume harms air quality and workers' health. The mobile fume extractor, is key. Especially the automatic pulse cleaning type shines with unique perks for industrial dust removal.

The mobile fume extractor uses an imported flame - retardant coated filter element. It does 0.3μm ultra - fine filtration. It catches welding and industrial dust well. The smooth surface stops dust buildup. With automatic pulse cleaning, it blows dust off the filter cartridge. This makes cleaning thorough and extends the filter's life. In metal casting workshops with lots of dust, it works great.

Look at models MLWF220FA and MLWF280FA. They have a pure copper core brand motor. It gives enough power. For example, MLWF280FA has 3.0KW power. It ensures good air volume (MLWF220FA 2200m³/h, MLWF280FA 2800m³/h). So, dust - laden air passes fast. Brand electrical components help the device run stably. In big welding lines, these mobile fume extractors meet high - load needs.

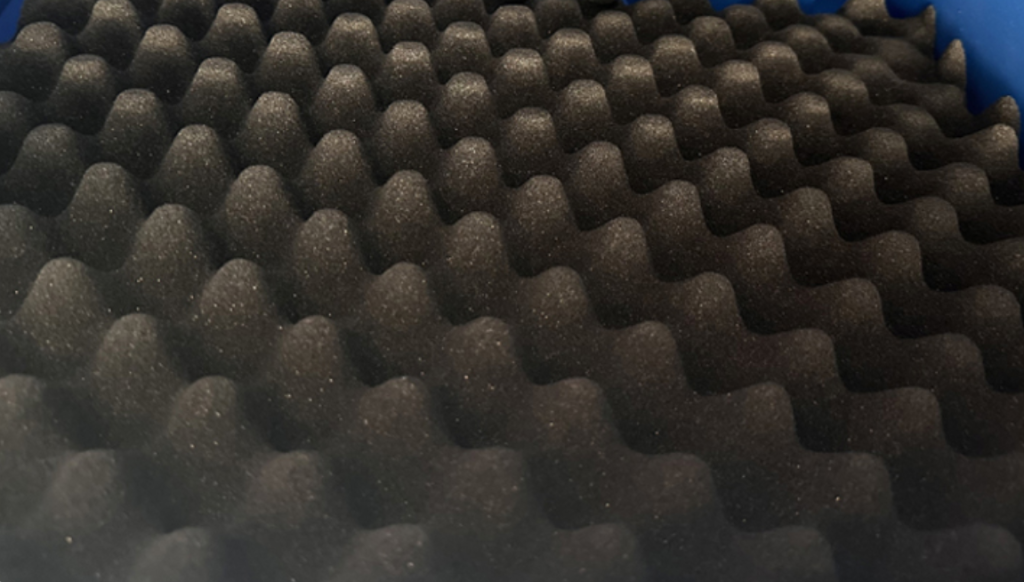

The sound - absorbing cotton design is great. Its fibrous, open - cell and fluffy parts soak up noise. This makes workshops quieter. It meets health rules and cuts noise for workers. In precision machining shops, it helps workers focus and protects instruments.

Some models have activated carbon filter cotton. It catches dust and adsorbs harmful gases. This boosts air quality. The low wind resistance design saves energy while cleaning well. In chemical and electronics welding, it handles dust and gases.

In workshops and labs, the extractor deals with welding fume fast. Its mobility suits different workstations. It helps firms meet env rules and keep workers healthy. Whether in small factories or big workshops, it's useful. In temporary welding jobs, it gets to work fast and keeps air clean.

From filter precision to dust cleaning, and power to noise reduction, this mobile fume extractor offers a good dust - removal solution. It pushes industrial production to be greener and healthier.