The single-station grinding workbench is a professional dust collector, and it works well in many industrial scenarios. For example, in hardware workshops, it handles small-batch precision grinding and easily collects metal dust from bolts and nuts. Meanwhile, in auto parts factories, it polishes gears and bearings, keeping the air clean there. For handicraft makers, it polishes wood carvings and grinds jade, catching fine dust to protect workers. Even in labs, it performs stably, and its dust collection effect is great for precise sample processing.

The single - station grinding workbench is a high - quality dust collector. It has three models: MLWF100D, MLWF150D and ML200D. They meet different production needs.

MLWF100D has a 1.1KW motor, runs on 220V/50Hz, reaches 1500m³/h air volume, weighs 105Kg and measures 10006001000mm, fitting small workshops well.

In contrast, MLWF150D comes with a 1.5KW2 motor, adapts to 380V/50Hz, offers 2500m³/h air volume, weighs 150Kg and measures 1500800*1000mm, suiting medium-scale grinding.

Meanwhile, ML200D has a 2.2KW2 motor, works with 220V/50Hz, features 3000m³/h air volume, weighs 260Kg and is 2000800*1000mm, handling large-volume tasks.

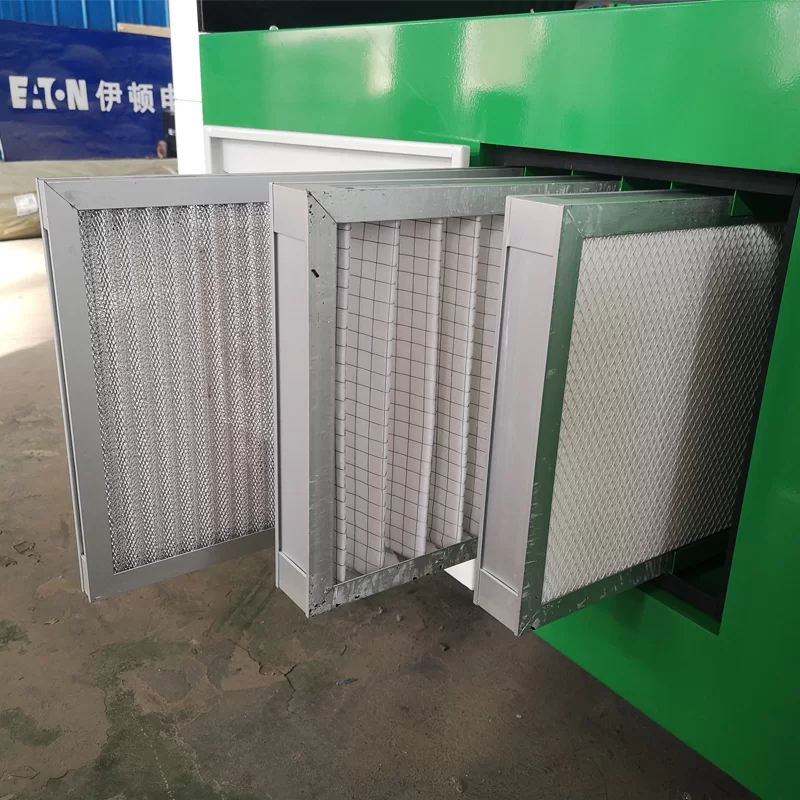

All models have 0.3μm filtration precision. Their filter elements use aluminum alloy, primary and high - efficiency materials. They lock tiny dust in the dust collector. This stops air pollution in workshops. In 16m² areas, noise stays ≤75±3dBA. This creates a quiet workspace.

The dust collector's filtration system is a big highlight. It uses a triple system that includes an aluminum alloy flame arrester, a primary filter, and a high-efficiency filter. First, the flame arrester blocks large particles and resists fire. Then, the primary filter catches medium-sized dust. Finally, the high-efficiency filter traps tiny particles. This step-by-step cleaning achieves great purification, forming an excellent dust collector system that keeps workshop air clean.

The dust collector's workbench can be customized, which greatly boosts its practicality. For example, the table rotates, allowing workers to adjust grinding angles more accurately—this directly improves precision and quality. Additionally, the table surface has various hole designs, including round, square, and long strip holes. Different holes fit different tasks: round holes collect dust from small parts, while long strip holes work better for long workpieces. What’s more, the surface material offers options like stainless steel, brass, nylon, or polyurethane: stainless steel is durable for heavy work; brass resists wear for soft metal grinding; nylon and polyurethane avoid scratches, suiting sensitive surface polishing.

The single-station grinding workbench focuses on noise control by using sound-absorbing cotton. This cotton has fibrous material, open cells, and a fluffy texture—features that let it absorb noise well. When noise passes through the cotton, it reflects and gets absorbed in the porous structure, reducing noise significantly. As a result, the equipment runs quietly, lessening noise’s impact on workers' health and improving the working environment.

The dust collector is equipped with a brand motor, which ensures stable operation. The motor passes strict quality tests, performing well with low failure rates and long lifespans—this cuts down maintenance times. Moreover, it runs with low noise, matching the equipment's overall noise reduction design to keep the workspace quiet. Meanwhile, stable motor operation ensures steady air volume, preventing dust collection from being affected by unstable power.

Choosing a good dust collector matters for enterprises because it improves production efficiency and protects workers' health. The single-station grinding workbench stands out due to its great performance: it fits many scenarios, meeting different industry needs, and has excellent parameters for efficient, stable dust collection. Its advantages are clear too, including an efficient filtration system, customizable workbench, good noise reduction, and reliable motor—all of which make it work great in real use.

Furthermore, it helps enterprises meet environmental standards, lowers the risk of occupational diseases, and builds a good working atmosphere. In the long run, it also cuts production equipment maintenance costs, as less dust means less wear on parts. For these reasons, the single-station grinding workbench is a smart choice, suiting enterprises chasing high-quality production.