Los procesos industriales de rectificado generan cantidades significativas de polvo y partículas, lo que supone un riesgo tanto para la salud de los trabajadores como para el rendimiento de los equipos. Los sistemas eficaces de purificación de polvo son esenciales para mantener un entorno de trabajo seguro y eficiente.

The layout of the equipment should be reasonable and compact, focusing on energy-saving measures and efficient use of resources. The equipment must ensure long-term reliability and comply with the pollutant emission standards outlined in the environmental impact assessment report.

The Grinding and Polishing Dust Removal Table is designed to effectively manage dust generated during the grinding and polishing processes. It aims to enhance workplace safety and maintain air quality by capturing and filtering dust particles at the source.

Industries often deal with a variety of pollutants that may require different purification methods, making it difficult to design a one-size-fits-all solution.

Ensuring that new purification technologies seamlessly integrate with existing processes and infrastructure can be a significant challenge.

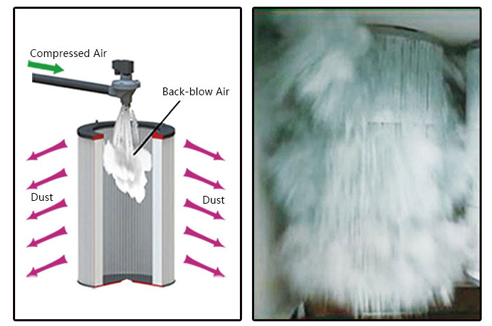

Automatic ash cleaning

Gran volumen de aire

Fácil de mantener