Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Industrial Dust Collectors are a type of air pollution control equipment used in factories, plants, warehouses and other industrial or commercial settings to meet environmental and workplace safety requirements. Effective dust collection systems control, reduce, and remove potentially harmful particulate matter and fumes from gases from a manufacturing process or the air and the surrounding environment during production and manufacturing. The equipment is specifically designed to purify and filter hazardous dust and fine particulate contaminant matter released into the work environment or atmosphere to maintain and improve air quality.

Types of pollutants can differ by industry. Therefore, Industrial Dust Collector designs are specific to the extraction method required for each industry. Dust Collector systems work in general by drawing dust and particulates from the air through a filter that first captures and separates the matter, and then discharges purified air back into the workplace or environment. The objective of each design application is essentially the same-to filter, separate, and capture dust and particulate matter and release sanitized air.

Basic components of dust collectors include a blower, dust Filter Element, filter cleaning system, dust receptacle and dust removal system. Five common types of dust collection equipment are fabric filter baghouses, inertial separators (like mechanical cyclones), cartridge collectors, wet scrubbers, and electrostatic precipitators.

Baghouse dust collectors come in various designs and are the most commonly used system because of their 99% efficiency.

Dust collection is critical to a number of industrial sectors such as woodworking, agriculture, food processing, pharmaceutical, recycling, cement and rock products, metal fabrication, mining, and chemical processing among many others. Dust collectors referred to as filter receivers are essential parts of processing systems in many thermal and size reduction applications and as receivers for pneumatic conveying.

Moland is a professional industrial dust collectors manufacturer. Our dust collectors are cartridge dust collectors and mainly used for metal dust and fume collection.

Divide according to filter form, Moland has cartridge dust collectors and multi-layer filter plate dust collectors. As most of our dust collectors are cartridge dust collectors, here, we only introduce you our cartridge dust collectors.

Cartridge Collectors

For certain applications, cartridge collectors are a type of fabric filter designed for specific applications. They offer an advantage where smaller space requirements are necessary for the same airflow of a larger baghouse system. Cartridge collectors pack more fabric area into a smaller space, utilize fewer filters, and filters can be changed from outside of the collector, which minimizes safety hazards. These features also reduce the time to change the filters and associated labor costs. Find cartridge collectors in commercial and industrial environments with very fine-to-light dust and moderate dust-like powder coating, metalworking, woodworking, fume collection, thermal spray, pharmaceutical manufacturing, among other processes.

Divide according to dust cleaning mode, Moland has manual cleaning dust collectors, automatic pulse jet dust collectors and all-round rotary back blowing dust collectors.

Manual dust collectors are mainly Portable Fume Extractor, which are used for welding fume and smoke extraction. When using this dust collectors, you need to remove the filter and cleaning it manually.

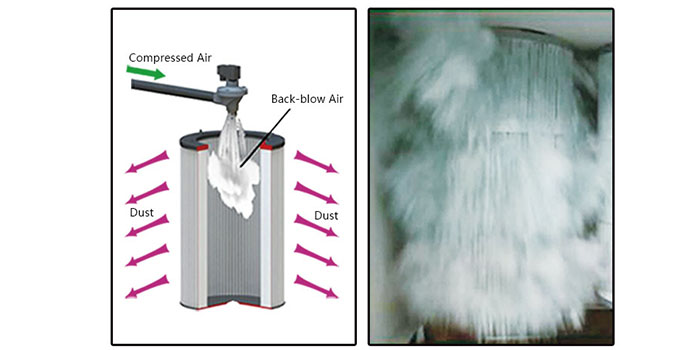

A reverse pulse (often called a pulse jet or reverse jet) filter cleaning system is a simple action that has significant results. A simple explanation of a reverse pulse filter cleaning system is as follows: in normal dust collector operation, air flows from the outside of the filter media to the center of the filter. The dust is filtered out and left on the outside surface of the filter. To clean off this dust, a blast of compressed air is shot down the center of the filter and works outward taking the dust off of the surface of the filter. In a downflow dust collector, the dust is captured by that downward airflow and eventually deposited in the collection hopper.

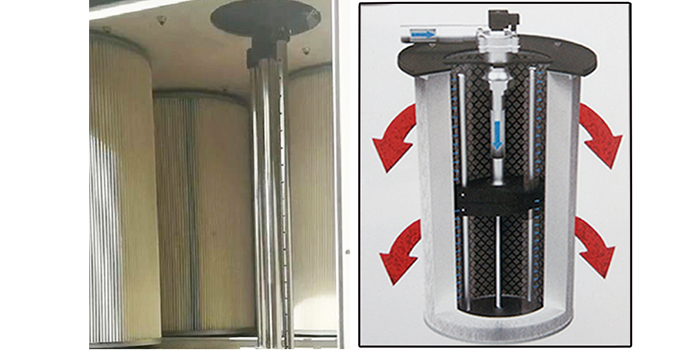

Compared to pulse jet cleaning, rotary back blowing cleaning mode is more thoroughly. There are many holes on the cleaning device, which makes the compressed air entering the filter cartridge more uniform.

If you want to know more about our products, welcome to contact us.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.